You have always equated heavy-duty tires with thick rubber and deep treads. But as raw material costs skyrocket, these traditional "quality" features are making your tires impossibly expensive, crushing your margins.

When raw materials dominate costs, tire design fundamentally shifts from a pure "performance-first" approach to a "cost-efficient performance1" model. This forces engineers to innovate for durability and strength without simply adding more expensive material, changing the very definition of a well-designed tire.

I remember visiting a partner factory a couple of years ago. They had two large OTR tires on display. One was their classic, best-selling model—it was bulky, thick, and looked indestructible. The other was a new prototype. It looked leaner, almost less impressive. The chief engineer told me, "The old tire is a beast, but it's a dinosaur." He explained the new, leaner model used an advanced compound2 and a smarter internal structure to deliver 95% of the old tire's performance while using 20% less rubber. In a volatile market, that 20% wasn't just a cost saving; it was their key to survival. That conversation stuck with me. We are no longer in an era of brute force design; we are in an era of engineering elegance driven by necessity.

Is a Thicker Carcass Still the Best Sign of a Quality Tire?

You've always told your customers that a heavier tire with a thicker carcass is stronger. It's an easy way to demonstrate value. But now, that extra weight is becoming a heavy burden on your price list.

No, a thicker carcass is not always the best sign of quality anymore. When raw material costs are high, an overly thick design becomes a cost trap3. It dramatically increases the tire's price without adding proportional performance, making smarter, more efficient designs far more valuable.

The old logic was simple: more rubber equals more protection, so a thicker tire is a better tire. This held true when rubber and steel were relatively cheap commodities. But today, that thinking is a liability. A "cost trap3" is when a feature that once signaled quality now primarily just adds expense. For example, if the price of natural rubber doubles, a tire with 10% more rubber doesn't just get 10% more expensive—the cost increase is magnified and passed directly to you. This impact varies significantly across different tire types because they use different volumes of material. OTR tires, which are virtual mountains of rubber, are extremely sensitive to these price shocks. Agricultural and industrial tires are also heavily affected, forcing a complete rethink of their design philosophy.

How Different Tire Segments Absorb Costs

| Tire Segment | Typical Rubber Volume | Sensitivity to Rubber Price Hikes | Key Design Shift |

|---|---|---|---|

| OTR Tires | Very High | Extreme | Focus on new compounds and structural optimization4 to reduce weight. |

| Agricultural Tires | High | Very High | Balancing tread depth5 for traction with material-efficient patterns. |

| Industrial Tires | Medium | High | Creating durable, leaner profiles6 that resist wear without excess bulk. |

Is "Design for Performance" Being Replaced by "Design for Cost"?

Your engineering team and suppliers have always aimed to create the toughest, highest-performing tire possible. But now, you're finding that these top-tier designs are becoming too expensive to produce and sell profitably.

Yes, in many ways, the traditional "design for performance" mantra is being replaced by "design for cost efficiency." The primary goal is no longer achieving maximum performance at any cost. Instead, it's about delivering reliable, application-specific performance7 within a strict material budget8.

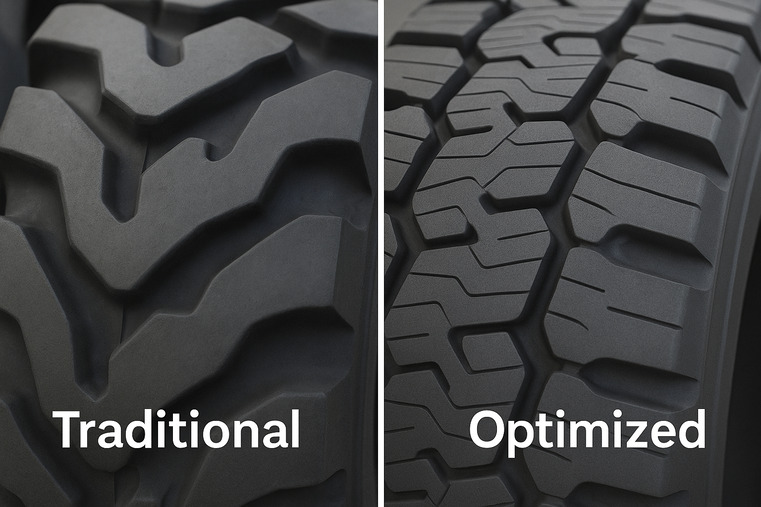

For decades, the benchmark of a great tire engineer was the ability to push performance limits. The goal was to build the most indestructible tire imaginable, with deep, aggressive tread blocks and heavily reinforced sidewalls9. This was a point of pride. Today, the challenge has fundamentally changed. The new engineering hero is the one who can say, "I delivered the performance you need, and I did it using 15% less material." This shift redefines key tire features. Deep tread blocks are no longer just about maximum grip; their shape is now calculated by complex software to provide optimal traction with the minimum possible rubber volume. Reinforced sidewalls are not just about adding layers of rubber; they're about using stronger, lighter materials in a smarter structural layout. The future shape and feel of tires will be dictated as much by the commodity markets as by the engineers' desire for pure performance.

Conclusion

The rising cost of raw materials is forcing a revolution in tire design. The future belongs not to the bulkiest tires, but to the smartest, most cost-efficient designs.

Understanding cost-efficient performance can help you appreciate modern tire innovations that balance cost and quality. ↩

Explore how advanced compounds enhance tire performance while reducing material costs, a key to modern tire design. ↩

Learn about cost traps and how they affect tire pricing and performance, crucial for making informed purchasing decisions. ↩

Discover how structural optimization leads to lighter, more durable tires, essential for today's market demands. ↩

Explore the relationship between tread depth and performance to make better tire choices for your vehicle. ↩

Understanding leaner profiles can help you appreciate modern tire efficiency and performance improvements. ↩

Understanding application-specific performance helps you choose the right tire for your needs, maximizing efficiency and safety. ↩

Learn about material budgets and their impact on tire design, crucial for balancing performance and cost. ↩

Discover how reinforced sidewalls enhance tire durability and performance, making them a smart choice for various applications. ↩