A batch of OTR tires looks identical, but some crack or wear out inexplicably fast. This inconsistency is a constant risk to your procurement budget1 and your brand’s reputation.

Compound consistency2 is critical because it dictates a tire’s core properties like heat resistance3 and durability4. Even microscopic variations in the rubber formula5 are the primary reason why visually identical tires perform so differently under stress, leading to unpredictable failures and inconsistent wear life.

I've seen this countless times over my 13 years in this business. A procurement manager will show me two failed tires from the same production batch. One has a clean tear from an impact, but the other looks like it degraded from the inside out. The issue isn't the tire's shape or tread; it’s the invisible foundation—the rubber recipe itself. A single OTR tire isn't made from one type of rubber. It's a complex structure of multiple specialized compounds, and if any one of them is inconsistent, the entire tire is compromised.

Why Does a Single Tire Need So Many Different Compounds?

You might think an OTR tire is just one big piece of tough rubber. But this assumption leads to overlooking where the real quality issues begin—deep inside the tire's structure.

An OTR tire uses multiple, distinct rubber compounds because different parts of the tire have different jobs. The tread needs to be cut-resistant, the sidewall must be flexible, and the bead area requires high strength to hold the tire to the rim.

I often explain it to clients like this: you wouldn't build an entire house out of just concrete. You need different materials for the foundation, walls, and roof. A tire is the same. The part that meets the rocks and debris (the tread) needs a different "recipe" than the part that flexes constantly (the sidewall). A cheap tire might use fewer, less-specialized compounds to save money, but that’s a direct trade-off for performance and safety. Understanding this multi-compound structure is the first step to identifying why consistency is so complex, yet so important.

The Job of Each Compound

Each compound is a unique formula engineered for a specific task. If a supplier gets any one of these wrong, it creates a weak link in the chain.

| Compound Location | Primary Function | Consequence of Poor Consistency |

|---|---|---|

| Tread | Resist cuts, abrasion, and heat | Rapid wear, chipping, or chunking under load. |

| Sidewall | Provide flexibility and ozone resistance | Premature cracking, leading to air loss or blowouts. |

| Bead Area | Ensure high strength and a firm grip on the rim | Bead failure, tire slipping on the rim, safety hazards. |

| Under-tread | Bond the tread to the casing and dissipate heat | Separation of the tread from the tire body. |

True quality comes from ensuring every one of these compounds is perfect, every time.

What Goes Wrong During the Mixing Process?

You know different compounds are used, but the tires still come from the same factory. So why do they fail differently? The problem often starts in the factory's mixing room.

Inconsistencies are born when mixing time is too short, temperature drifts, or carbon black isn't evenly dispersed. These process failures create "bad batches" of rubber that lead to poor heat resistance3, cracking, or separation, even if the tire looks perfect.

When I audit a factory, I spend a lot of time in the mixing department. This is where the foundation is laid. A less diligent supplier might try to speed up mixing times to increase output. But if you cut the mixing time by even a minute, the carbon black—which gives the rubber its strength—might not disperse fully. You get microscopic clumps, creating weak points you can't see. The same goes for temperature; a few degrees off and the chemical bonds don't form correctly. This is why we mandate automated mixing cycles and temperature controls from our partners. It's not something you can leave to chance.

The Four Main Mixing Failures

These four issues are the root cause of most compound-related tire failures. A good supplier has strict controls to prevent every one of them.

- Insufficient Mixing Time: Ingredients are not fully homogenized. This is like having clumps of flour in cake batter—it creates weak spots throughout the rubber.

- Temperature Control Drifts: The mixing process6 generates intense heat. If not precisely controlled, the rubber can begin to cure prematurely (a process called "scorching"), ruining its properties.

- Uneven Carbon Black Dispersion: The most critical strengthening agent isn't evenly distributed, leading to inconsistent hardness and wear characteristics across the tread.

- Improper Storage: Mixed compound is sensitive. If stored too long or in the wrong conditions (e.g., too warm), its properties can change before it's even used to build a tire.

How Can You Verify a Supplier's Compound Consistency?

You can’t visit the mixing room for every order. So how do you protect your business from a supplier’s hidden inconsistencies? You have to rely on data and systematic verification.

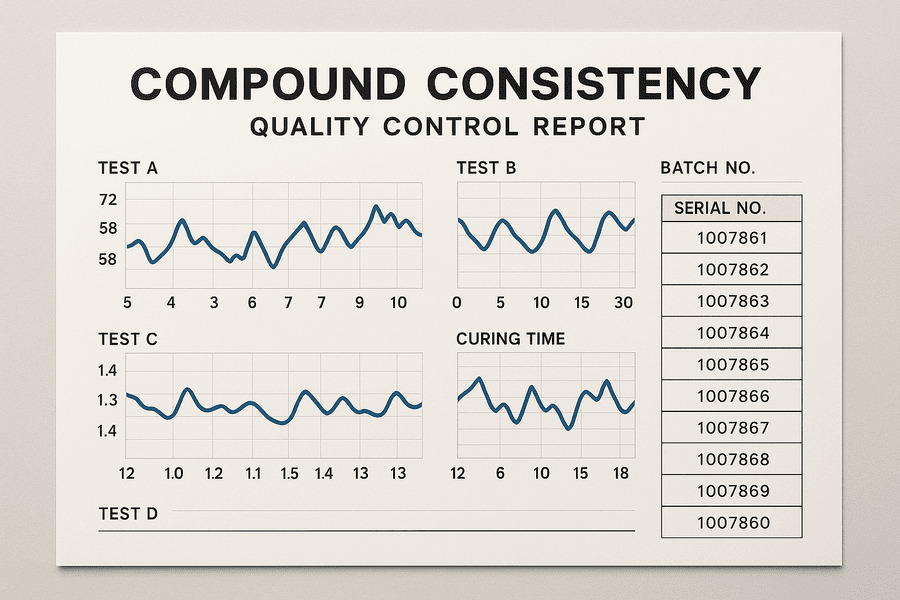

Verify a supplier's consistency by demanding batch-level testing7 reports for the mixed compound, not just the raw materials. A reliable partner will conduct tests on samples from every mix and link that data to each tire's unique serial number.

When a client asks me how we ensure consistency at Gescomaxy, I show them our data. We don't just trust the factory's process; we verify the output. We perform rheometer tests on samples from each rubber batch to check its curing characteristics. This data is logged and attached to the production run. If a tire fails in the field two years later, we can trace it back to the exact rubber batch and its specific test results. This level of traceability is the only true guarantee of compound consistency. If a supplier can't provide this, they can't promise reliable performance.

A Checklist for Compound Verification

Ask your supplier these questions. "Yes" is not enough—ask for proof in the form of data reports.

| Verification Method | What to Ask For | Why It Is Critical |

|---|---|---|

| Batch Rheometer Testing | "Show me the rheometer curve data for my last order's compound batches." | This is direct, scientific proof of whether the compound was mixed correctly and will cure as expected. |

| Carbon Black Dispersion Test | "What is your testing method and frequency for carbon black dispersion8?" | This confirms that the key strengthening agent is evenly distributed for consistent wear. |

| Compound Batch Traceability | "Can you trace a single tire's serial number back to its specific compound batch report?" | This proves they have a closed-loop quality system and demonstrates full accountability. |

Without this data-driven approach, you're buying a product based on hope, not evidence.

Conclusion

The real performance of an OTR tire is decided in the mixing room. True consistency only comes from a supplier who obsesses over compound data and can prove it.

Understand the financial implications of tire quality on procurement budgets. ↩

Understanding compound consistency is crucial for ensuring tire durability and performance. ↩

Explore how heat resistance plays a vital role in tire longevity and safety. ↩

Learn about the key factors that contribute to tire durability and how to choose the right tires. ↩

Discover how variations in rubber formula can impact tire performance and safety. ↩

Understand the critical mixing process and how it affects tire quality. ↩

Discover the importance of batch-level testing for ensuring tire consistency. ↩

Learn about the role of carbon black dispersion in enhancing tire strength. ↩