You've invested in a powerful, high-horsepower tractor, but in the field, it's slipping, churning mud, and burning fuel. The power isn't making it to the ground where it counts.

Heavy tillage requires deep-lug tires1 like the R-1W2 and R-23 because their taller treads bite deeper into soft, wet, or loose soil. This provides the necessary traction4 to transfer the tractor's immense torque into pulling power, significantly reducing wheel slip5 and maximizing fuel efficiency6.

I've seen it countless times in my 12+ years in this industry. A farmer buys a brand new 400-horsepower machine, but pairs it with standard R-1 tires7. Come spring plowing8, that powerful machine becomes an expensive mud-slinger9. The problem isn't the tractor; it's the handshake between the tire and the earth. For the toughest jobs, you need a tire that doesn't just roll over the ground—it needs to grab it. That's precisely what deep-lug tires1 are engineered to do.

How does a deeper tread actually improve traction4 in tough soil?

You look at R-1, R-1W2, and R-23 tires, and the most obvious difference is the lug height. But it's hard to justify the extra cost if you're not sure how that extra 25% or more of rubber actually translates to better performance.

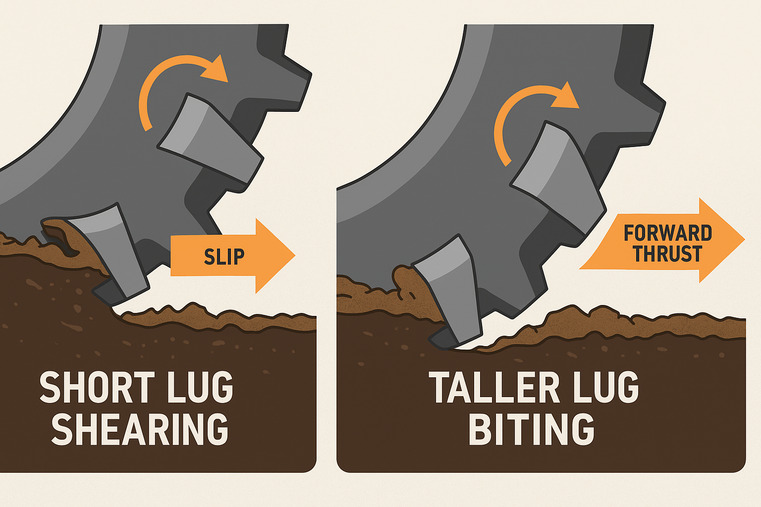

A deeper tread improves traction4 by acting like a paddle wheel. In soft or wet soil where a standard lug might slip, a taller lug bites deeper to find a firmer base or moves a larger volume of soil to generate forward thrust.

Think of it like this: trying to paddle a canoe with a ping-pong paddle versus a full-sized oar. The ping-pong paddle will just skim the surface, but the oar digs deep and propels you forward. In soil, a standard R-1 tread is fine for firm, dry ground. But when you get into wet, heavy soil during spring tillage, that R-1 lug can "shear" the mud—it spins inside the soil instead of gripping it. A deep R-1W2 or R-23 lug pushes against a much larger column of soil, creating the raw pulling power needed for implements like plows and deep rippers.

The Critical Difference: Grip vs. Slip

The goal is to convert engine power into work with minimal waste. Wheel slip is that waste, and tread depth10 is your primary tool for controlling it.

- Standard Lugs (R-1): These are the all-rounders. They have a lug height that provides a good balance of traction4, roadability, and tread life for general farm work in typical conditions. They rely on the soil having enough integrity to be pushed against.

- Deep Lugs (R-1W2 & R-23): These are specialists. Their value shines when the soil integrity11 is low.

Here’s a breakdown of how they compare in the conditions that demand high traction4:

| Tire Type | Lug Depth (Approx.) | Ideal Soil Condition | Primary Application |

|---|---|---|---|

| R-1 | Standard | Firm, dry to moderately moist soil | General planting, spraying, light tillage |

| R-1W2 | ~25% deeper than R-1 | Wet, soft, sticky, un-tilled soil | Plowing, deep ripping, heavy tillage12 |

| R-23 | ~2x deeper than R-1 | Extremely wet, muddy, flooded soil | Cane and rice farming, extreme mud |

Choosing an R-1W2 or R-23 isn't about buying a "better" tire in general; it's about matching the engineering of the tire to the specific, challenging conditions of heavy tillage12.

When is an R-1W2 tire the ideal choice over a standard R-1?

You stock R-1 tires7 because they cover most situations. But when a customer with a new, powerful tractor asks for something better for plowing8, you need to provide a solution that delivers real value.

An R-1W2 tire is the ideal choice when high-horsepower tractors (over 150 HP) are used for primary tillage13 in the wet conditions common in North America and Europe. It provides significantly more traction4 than an R-1 without the extreme specialization of an R-23.

The "W" in R-1W2 originally stood for "wet." This tire was specifically designed for the damp, heavy soils of Europe. It has since become the go-to tire for heavy draft work worldwide. As a supplier, I always advise my clients that if their customers are running large, ballasted tractors for primary tillage13, the R-1W2 is not an upgrade; it's the correct specification. Selling them a standard R-1 for this job is like selling running shoes to a mountain climber. It might work for a bit, but it's the wrong tool for the job and will lead to poor performance and customer dissatisfaction.

The Decision Matrix: Choosing Between R-1 and R-1W2

For a dealer or a purchasing manager, the decision comes down to the primary use case for the machine. Here's a simple way to think about it:

What is the machine's main job?

- Row-Crop Cultivation, Spraying, Planting: The tractor is operating on relatively firm, prepared soil. An R-1 is often sufficient and may offer better road wear and fuel economy for transport.

- Primary Tillage, Plowing, Ripping: The tractor is breaking new ground or working in soft, unpredictable conditions, often with heavy ballast. High traction4 is the number one priority. An R-1W2 is the professional choice.

What are the typical soil conditions?

- Mostly Dry, Firm Soil: R-1 provides a great balance of performance and longevity.

- Wet Spring & Fall Seasons: The ground is soft and traction4 is limited. The R-1W2's deeper lugs are essential to get a grip and reduce slip, which in turn saves significant amounts of fuel over a season.

By recommending the R-1W2 for these specific, demanding applications, you position yourself as an expert who understands how to maximize your customer's investment.

If R-1W2 is for wet soil, why not just always use an R-23?

You know that R-23 tires have the deepest lugs available, so it seems logical that they would offer the most traction4. But putting them on a tractor for standard plowing8 can actually cause more problems than it solves.

R-23 tires are too aggressive for most tillage operations. Their extremely deep lugs can excessively disturb the soil structure14, increase rolling resistance on firm ground, and wear very quickly on roads. They are highly specialized tools for near-liquid mud, like in rice paddies.

I once had a client in a non-rice growing region who insisted on ordering R-23 tires for his tillage tractors, thinking "more is better." A few months later, he called to complain. The tires were wearing out incredibly fast from the short road trips between fields, and his operators reported that in moderately wet soil, they actually dug down and got the tractor stuck faster than the old R-1W2s. This is a perfect example of why specialization matters. The R-23 is designed to find a hard bottom in a sea of mud. In soil, that same design can act like an auger.

The Right Tool for a Very Specific Job

The R-23 is an example of peak engineering for a narrow task. Using it outside of that task leads to poor outcomes.

- Soil Disturbance: The massive lugs of an R-23 can damage the soil profile in a typical field, disrupting the delicate balance needed for healthy crop growth. The R-1W2 is designed to grip without being overly destructive.

- Wear and Tear: Those huge lugs are not designed for abrasive surfaces. They will wear down rapidly on pavement or even hard-packed dirt roads, making them uneconomical for any farm that requires road transport.

- Ride Comfort and Efficiency: The ride quality of an R-23 on any hard surface is extremely rough. Furthermore, the energy needed to simply turn those massive treads on firm ground leads to poor fuel efficiency6.

The R-1W2 exists because it strikes the perfect balance for heavy tillage12—it offers the deep bite needed for wet soil without the extreme, and often negative, characteristics of a super-specialist R-23 tire.

Conclusion

For heavy tillage12, deep-lug R-1W2 and R-23 tires are essential tools, not upgrades. Choosing the right one—usually the versatile R-1W2—ensures a tractor's power translates into productive work, not wasted fuel.

Explore how deep-lug tires enhance traction and efficiency for heavy tillage operations. ↩

Learn about the R-1W tire's design and its advantages for high-horsepower tractors in wet conditions. ↩

Understand the specific applications of R-2 tires and why they may not be suitable for all conditions. ↩

Discover the importance of traction in farming and how it impacts productivity and fuel efficiency. ↩

Find out how to reduce wheel slip and improve the efficiency of your tractor operations. ↩

Discover strategies to enhance fuel efficiency in farming through proper tire selection. ↩

Explore the characteristics of R-1 tires and their applications in various farming scenarios. ↩

Learn effective plowing techniques and the role of tire selection in successful operations. ↩

Find out how improper tire selection can lead to inefficiencies and challenges in the field. ↩

Explore the relationship between tread depth and tire performance in various soil conditions. ↩

Understand the concept of soil integrity and its impact on agricultural practices. ↩

Learn about heavy tillage techniques and the equipment that supports effective soil management. ↩

Learn about primary tillage practices and the tire options that maximize efficiency. ↩

Understand the impact of tire design on soil structure and crop health. ↩