You see a tire as a big piece of rubber, a necessary but simple consumable. But this view is causing you to miss out on a technology that can directly boost farm profitability and efficiency.

A Tire Pressure Monitoring System (TPMS)1 turns a tire into a smart, data-generating asset. By providing real-time pressure and temperature data2, it allows farmers to optimize for fuel efficiency3, increase crop yields4, and track tire performance5, transforming it from a dumb consumable into an active contributor to the farm's bottom line.

For years, the most advanced tool we had for tire management was a manual pressure gauge. It was a reactive task—you check the pressure because you're supposed to, or because something looks wrong. But TPMS changes everything. It makes tire management proactive. It's not about preventing a flat anymore; it's about constantly fine-tuning a critical piece of equipment to get the best possible performance. This shift in thinking is as significant as the move to GPS guidance.

Is tire pressure just about preventing flats, or can it actually increase crop yield?

You inflate your tires to the manufacturer's spec and get to work. It seems simple, but that one-size-fits-all pressure is likely compacting your soil and quietly stealing a portion of your profits every year.

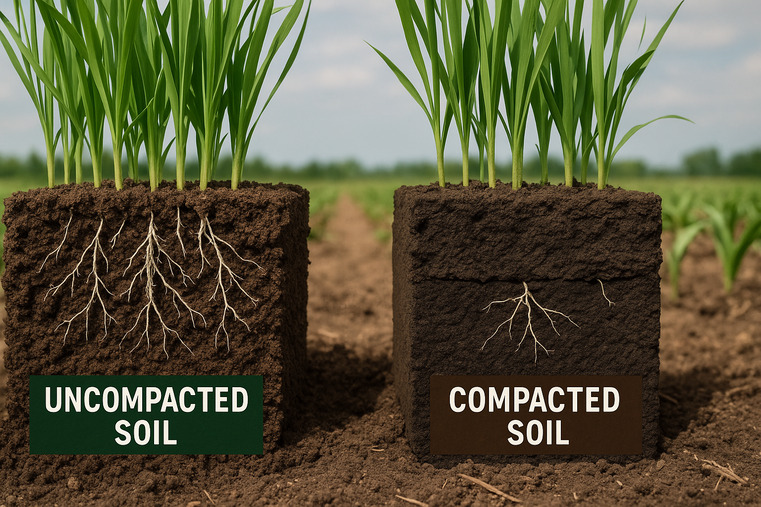

Optimizing tire pressure with TPMS can directly increase crop yield. By allowing farmers to run lower pressures in the field, it reduces soil compaction6, promotes healthier root growth, and improves traction, which all contribute to a bigger harvest.

I've walked through fields with farmers and you can literally feel the difference. In some areas, the ground is hard as a rock. In others, it's loose and healthy. That difference often comes down to equipment traffic with overinflated tires. The pressure you need on the road to be safe and fuel-efficient is the exact opposite of what you need in the field. TPMS makes it possible to manage this difference perfectly. It gives the farmer the confidence to lower pressure to the optimal level for soil health, knowing they will be alerted if it becomes unsafe. This isn't just about tires anymore; it's about agronomy.

From Maintenance Task to Yield Lever

The right pressure changes the tire's footprint, spreading the machine's weight over a larger area. This is the key to protecting the soil. An overinflated tire acts like a hammer, while a correctly inflated tire acts like a snowshoe.

Here is how pressure choices directly impact your farm's productivity:

| Tire Pressure Scenario | Impact on Soil | Impact on Yield |

|---|---|---|

| High (Road Pressure) | High ground pressure, deep soil compaction6. | Stunted root growth, poor water absorption, lower yield. |

| Low (Field Pressure) | Low ground pressure, minimal soil compaction6. | Healthy root systems, better water/nutrient access, higher yield. |

| Incorrectly Low | Risk of tire damage, poor handling. | Potential for downtime, reduced efficiency. |

TPMS, especially with a Central Tire Inflation System (CTIS)7, creates a closed loop. The system tells the farmer the ideal pressure for their current task and location. This transforms tire pressure from a static maintenance checklist item into a dynamic, yield-optimizing tool that works for you every minute of the day.

How does real-time data turn a tire from an expense into a managed asset?

You budget for tires as a major expense, a consumable to be replaced when it wears out or fails. But this treats them like a cost to be minimized, not an asset to be managed for maximum return.

Real-time data from TPMS provides a constant stream of information on pressure and temperature. This data allows for the precise calculation of cost-per-hour, enables predictive maintenance8, and verifies correct usage, turning an unpredictable expense into a fully transparent and manageable asset.

I work with fleet managers who used to tear their hair out over unexpected tire failures. A single, sudden blowout on a large combine during harvest can cost tens of thousands of dollars in downtime. TPMS changes this game completely. A sensor that detects a slow leak or a gradual increase in temperature (a sign of internal damage) can trigger an alert long before failure. This allows maintenance to be scheduled. It turns a catastrophic, budget-wrecking event into a planned, manageable repair. When you can measure performance, predict lifespan, and prevent failure, you are no longer just "using" a tire; you are managing an asset.

The Shift to Total Cost of Ownership (TCO)

With data, the conversation changes from "What does this tire cost?" to "What is this tire's TCO?". Data from TPMS is the missing ingredient needed to calculate this accurately.

- Performance Tracking: Are your tires being run at the right pressures for each job? TPMS provides an objective record. You can see if operators are following best practices, ensuring you get the performance you paid for.

- Predictive Maintenance: Temperature alerts can signal a failing bearing or an internal tire separation weeks before it becomes critical. Pressure loss alerts turn a sudden flat into a scheduled top-up.

- Lifecycle Analysis: By tracking hours of use, average load, and operating conditions, you can build a true performance profile for different tire brands and models. This allows you to make future purchasing decisions based on hard data, not just the initial price tag.

A tire with TPMS is no longer a black box. It's a data source that helps you lower your risks and optimize your investment.

Is the future of tires about better rubber or smarter data?

You're a dealer or distributor choosing which tire brands to carry. For decades, the decision has been based on tread compounds, ply ratings, and durability. But that entire competitive landscape is about to change.

The future of tire competition will be fought over data capabilities9, not just rubber quality. A good tire will be table stakes; a smart tire that integrates with the farm's data ecosystem to provide actionable insights will be the winner.

As a supplier with over 12 years of experience, I can see this shift happening right now. My most forward-thinking clients are no longer just asking for high-quality tires; they're asking for solutions. They want to know how our products can integrate into their customers' precision farming operations10. The tire is becoming another sensor on a highly connected, data-driven machine. A supplier who only talks about rubber and treads will soon be left behind by the supplier who can talk about APIs, data integration11, and fuel-saving algorithms12. This is a massive opportunity for those who are prepared.

Competing in the Age of Data

The value is moving from the physical object to the information it provides. For suppliers, distributors, and manufacturers, this requires a new strategy.

- Embrace Integration: Your products need to "talk" to other systems. This means working with farm management software, telematics providers, and equipment manufacturers to ensure your TPMS data is accessible and useful.

- Develop Data-Driven Solutions: Don't just sell a sensor; sell the insight. Can you offer a service that analyzes a fleet's tire data and provides recommendations for saving fuel or extending tire life? That is a powerful value proposition.

- Train for a New Conversation: Your sales team and your dealers need to be equipped to talk about technology and ROI, not just tire sizes and load indexes. They need to be consultants who can help farmers understand how this new data stream makes them more profitable.

The winning tire of tomorrow won't just be the toughest; it will be the smartest.

Conclusion

TPMS is transforming agricultural tires from passive rubber products into active data assets. Embracing this technology is essential for improving farm efficiency and for suppliers who want to lead in the future.

Explore how TPMS technology can enhance tire management and farm efficiency. ↩

Learn how real-time data can optimize farming operations and increase yields. ↩

Discover strategies to enhance fuel efficiency and reduce operational costs. ↩

Find out innovative methods to boost crop yields through modern technology. ↩

Understand the key elements that influence tire performance and longevity. ↩

Explore the impact of soil compaction on crop health and productivity. ↩

Learn how CTIS can enhance tire management and improve farm efficiency. ↩

Discover how predictive maintenance can prevent costly equipment failures. ↩

Discover the shift towards data-driven solutions in the tire market. ↩

Learn about the integration of tire technology in precision farming. ↩

Understand the significance of data integration for modern farming practices. ↩

Explore how fuel-saving algorithms can enhance efficiency and reduce costs. ↩