You bought tires at a rock-bottom price, but now there's a problem. The supplier is on another continent, and the support is non-existent. Your operations are bleeding money.

The global trade is shifting from a "lowest price" to a "best value" model. Suppliers win by offering localized inventory1, rapid on-site engineering support2, and integrated services that reduce your long-term operational costs3 and risks.

I’ll never forget a call I got late on a Friday. It was from a new client, a manager at a large equipment manufacturer. They had just switched to a new, cheaper tire and wheel supplier. A full container had arrived, but the wheels wouldn't mount correctly on their new tractor model. Their assembly line was completely stopped. Their "low-cost" supplier was unresponsive, thousands of miles and a dozen time zones away. We had one of our engineers on a plane that Sunday. By Tuesday, he had identified the issue and proposed a modification. That’s when the client realized the true cost of "cheap." The savings on the product were wiped out in a single day of downtime. This experience is why our entire business model is built around service, not just price.

Why Are OEMs Prioritizing Proximity Over Price?

Your assembly line is down waiting for a response from an overseas supplier. Every hour of delay costs you thousands, and your production targets are slipping further away each minute.

Original Equipment Manufacturers (OEMs) now reward supply chain resilience4 and rapid problem-solving. A supplier with nearby plants and fast on-site engineering response dramatically reduces production risks5, making proximity a critical factor over pure cost.

The old way was simple: find the cheapest product anywhere in the world. But recent global disruptions have shown how fragile that model is. For an OEM, a stopped production line is a financial disaster. They can't afford to wait weeks for a solution to a technical problem. That's why the conversation has changed. When I talk to OEMs now, their first questions are about our engineering support and response times. They want to know we can have a technical expert at their factory within 48 hours to solve a fitment issue or a performance problem. This is a massive shift. They are willing to pay a premium for the insurance that this proximity provides. It’s not just about geography; it’s about being a responsive, integrated partner in their manufacturing process, not just a faceless supplier from a catalog.

The True Cost: Price vs. Proximity

| Factor | Low-Cost Overseas Supplier | Localized Service Partner |

|---|---|---|

| Response Time | Days or Weeks | Hours |

| Problem Solving | Remote (email, phone) | On-Site, Hands-On |

| Downtime Risk | High | Low |

| Relationship | Transactional | Collaborative Partnership |

| Real Cost | Low initial price + high potential downtime cost | Higher initial price + low operational risk |

How Can Value-Added Services Prove a Supplier's Worth?

Your new tires are performing, but you have no data to prove it. You can't optimize your fleet, predict maintenance, or justify your purchasing decisions to management with hard numbers.

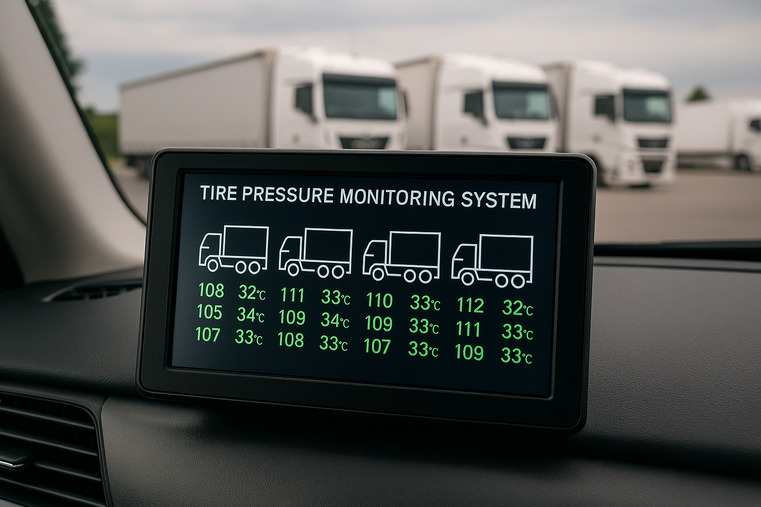

Services like TPMS readiness6, extended warranties7, and 24/7 support8 are direct proof of a supplier's commitment. They provide performance data, reduce financial risk, and guarantee help is there when you need it, creating value far beyond the tire itself.

Anyone can sell you a round, black piece of rubber. But a true partner helps you manage it as a valuable asset. This is where value-added services9 come in. For example, we ensure our tires and wheels are ready for Tire Pressure Monitoring Systems (TPMS). This shows we understand our clients' need for data to manage fuel efficiency and prevent catastrophic failures. We're not just selling a product; we're providing a component for their larger operational system. Furthermore, offering an extended warranty isn't just a marketing gimmick. It's a statement of confidence in our product quality. It tells the purchasing manager that we are willing to share the risk with them. When you combine this with a dedicated 24/7 support8 line, the message is clear: we are here to support your operation for the entire life of the product, not just until the invoice is paid.

Beyond the Product: What to Look For

| Service Feature | What It Means | The Benefit to You |

|---|---|---|

| TPMS/ATMS Readiness | Tires/wheels are built to integrate with monitoring systems. | Enables data-driven fleet management, reducing fuel and maintenance costs. |

| Extended Warranty | The manufacturer guarantees performance for a longer period. | Reduces your financial risk and proves the supplier's quality claims. |

| 24/7 Technical Support | Expert help is available any time, any day. | Minimizes downtime by providing immediate solutions to operational problems. |

| On-Site Assembly | We can mount tires on wheels for you before shipping. | Saves you labor, time, and ensures correct fitment from the start. |

Conclusion

The smart money is no longer on the cheapest price. It’s on the best long-term value, proven through responsive service, risk reduction, and a true understanding of your operational needs.

Explore how localized inventory can enhance supply chain efficiency and reduce operational risks. ↩

Learn about the advantages of having immediate engineering support to solve production issues. ↩

Discover strategies to lower operational costs while maintaining quality and efficiency. ↩

Understand the significance of resilience in supply chains and how it affects business continuity. ↩

Learn about production risks and effective strategies to minimize their impact on operations. ↩

Find out how TPMS readiness can optimize fleet performance and prevent failures. ↩

Explore the financial advantages of extended warranties and their impact on supplier trust. ↩

Learn how round-the-clock support can minimize downtime and enhance operational reliability. ↩

Discover how value-added services can enhance supplier relationships and operational efficiency. ↩