You're a purchasing manager juggling separate suppliers for tires and rims, trying to save a few dollars. But assembly issues, customer complaints about leaks, and unexpected wear are eating up those savings.

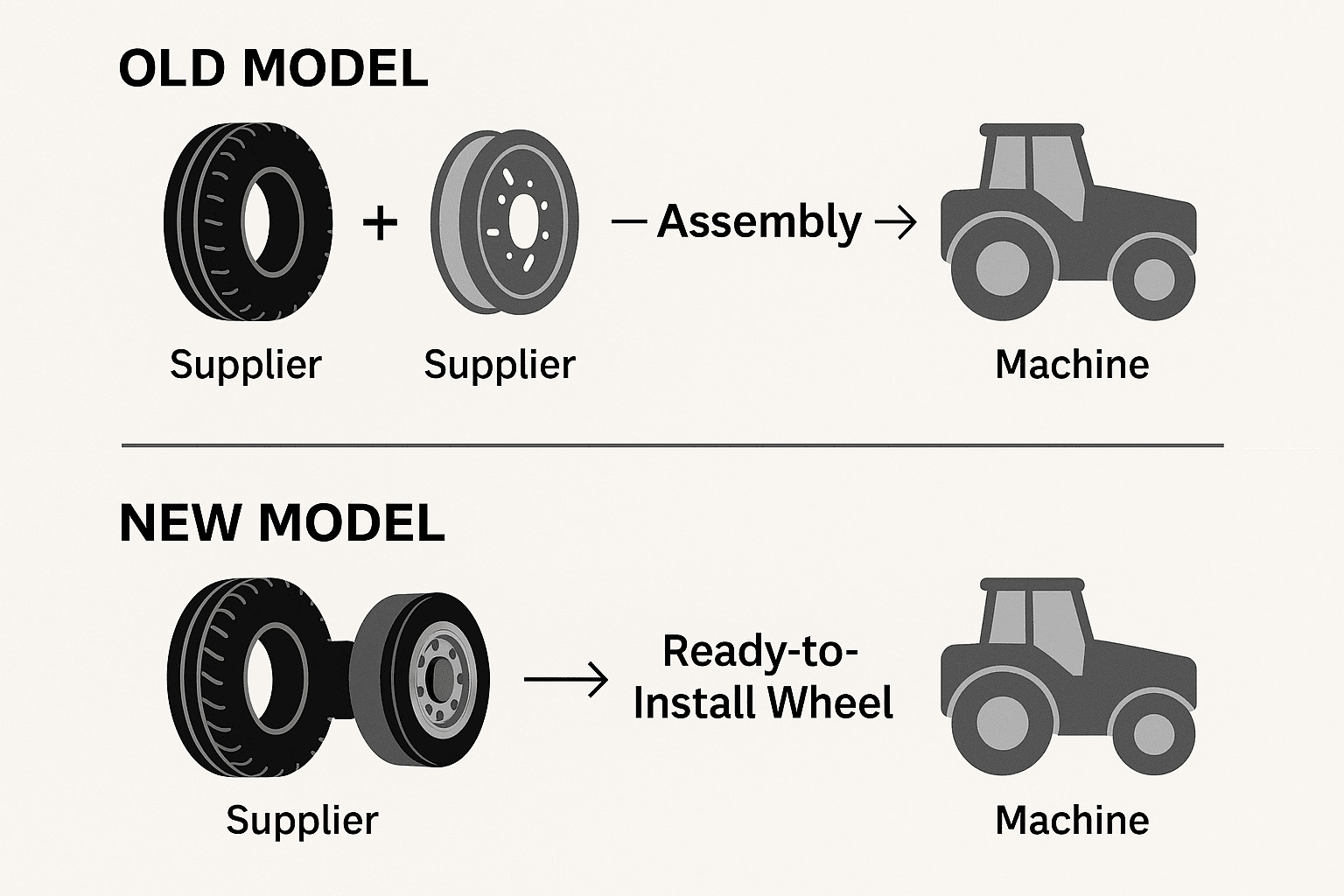

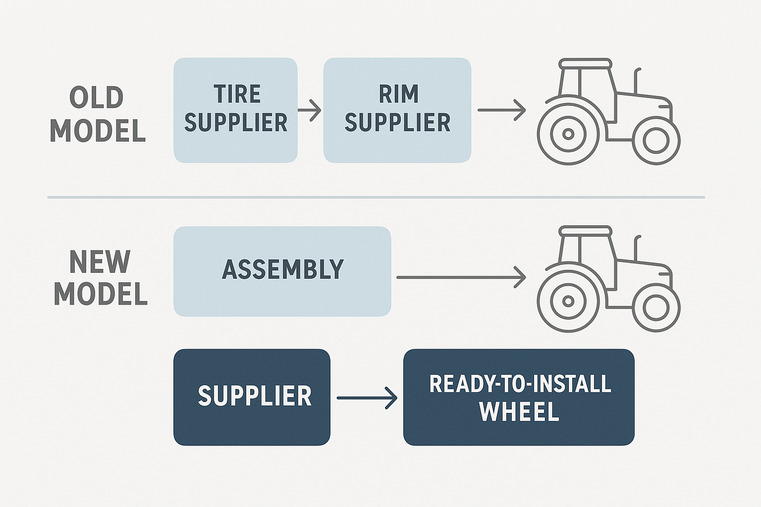

OEMs and dealers are shifting to complete wheel assemblies1 to eliminate risks from component mismatch. This single-source approach guarantees compatibility, simplifies logistics2, and places full accountability for performance3—from sealing to wear—on one trusted supplier, reducing total costs.

I saw this change happening firsthand. A large forklift manufacturer we work with was constantly battling slow leaks on their new machines. They blamed the tires; the tire supplier blamed the rims. Their production line was stalled over a frustrating, finger-pointing mess. We proposed a solution: let us deliver a fully assembled, tested, and guaranteed wheel set. The problem vanished overnight. That's when I knew the industry wasn't just changing; it was maturing. The focus was shifting from the price of the parts to the reliability of the system.

Aren't a tire and a rim just two separate parts?

You see a tire and a rim as two distinct items on a purchase order. You source them from different suppliers, believing you're optimizing the cost for each individual component.

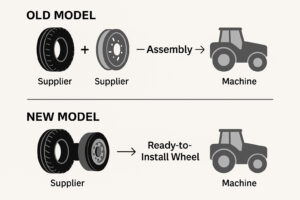

No, a tire and rim function as a single, integrated system. Their precise interaction is critical for load-bearing, transferring the machine's power into traction, and maintaining an airtight seal under immense pressure.

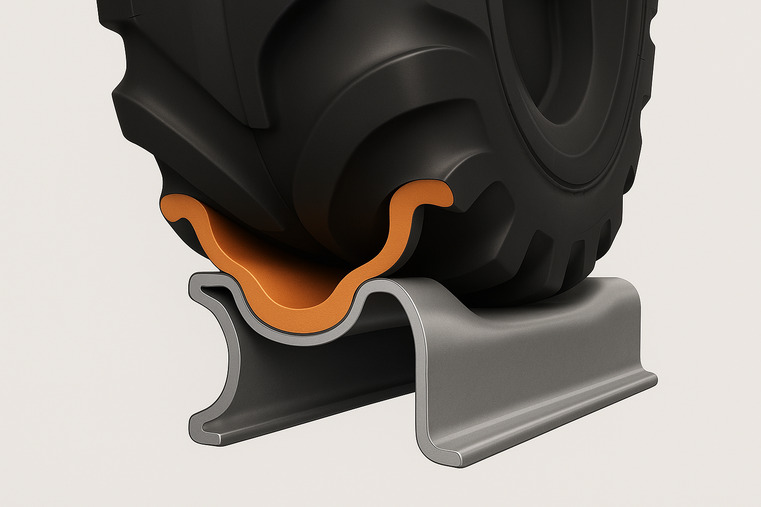

When we think about a wheel, we often separate the two in our minds. The tire is rubber, the rim is steel. But in operation, they are one. The tire's bead—the thick, reinforced inner edge—must seat perfectly against the rim's flange to create an airtight seal capable of holding tons of weight. The shape and tolerance of the rim directly impact how the tire's footprint meets the ground, which affects traction and wear. The entire assembly has to be perfectly balanced to transfer the engine's torque to the ground without vibration or slippage. If one component is out of spec, the entire system fails. I've seen cases where a rim that was just a few millimeters off caused chronic, untraceable wear patterns on a perfectly good tire. They aren't two parts working together; they are two halves of a single functional unit.

The Wheel as a Unified System

| Component | Individual Function | System Function |

|---|---|---|

| Tire | Provide grip, cushion ride | Flexes to create a contact patch for traction |

| Rim (Wheel) | Mount to the axle | Provides rigid structure for bead seating & load |

| Assembly | (Not applicable) | Maintains seal, transfers torque, bears load |

Viewing them separately ignores the physics of how they actually perform their job.

You've secured great prices on tires from one vendor and rims from another. You feel like you've won. But now your workshop is reporting mounting difficulties and early failures.

Buying components separately introduces three major risks: bead sealing failures4 causing slow leaks, uneven wear from load imbalance due to slight mismatches, and torque mismatch5 that can lead to slippage between the tire and rim.

This is where "saving money" up front gets expensive. I've seen it countless times. First is the bead sealing failure. Even a tiny variation in the rim diameter or flange angle can prevent a perfect seal, leading to slow, persistent leaks that cause downtime and premature tire failure from under-inflation. Second is uneven wear from imbalance6. A tire and rim must be perfectly concentric. If the manufacturing tolerances don't align, you get a slight wobble—often invisible to the eye—that creates high spots and uneven wear, drastically shortening the tire’s life. Third is torque mismatch5. In high-torque applications like loaders or farm tractors, a poor fit can allow the tire to slip on the rim, which not only causes damage but also represents a massive loss of power and efficiency. These aren't hypothetical problems; they are the daily, costly reality for workshops that have to assemble mismatched components.

How does buying a complete set solve these problems?

Your team is wasting valuable time and resources dealing with compatibility issues. You need a way to de-risk your procurement and assembly process and ensure reliability for your customers.

Purchasing a complete wheel set gives you single-point accountability7. The supplier guarantees that the components are perfectly matched, and the assembly is performed to OEM-level standards8 for balance and sealing, eliminating all compatibility guesswork.

When you buy a complete assembly from a single, qualified supplier, the dynamic changes completely. The responsibility is no longer divided. If there's a leak, it's the supplier's problem. If there's a balance issue, it's the supplier's problem. You get verified compatibility9 before the product ever reaches your facility. At Gescomaxy, for instance, we don't just grab a tire and a rim. We match them based on detailed engineering specs and then assemble them on professional-grade machinery. Each assembly can be tested for leaks and balance before it's shipped. This OEM-level consistency means that every wheel you receive is a "plug-and-play" solution. It bolts directly onto the machine, ready to work. This eliminates workshop variables, reduces labor costs, and provides a level of quality assurance10 that is impossible to achieve when buying parts separately.

Is this shift changing the role of a tire supplier?

You're used to buying tires as a commodity, focusing on price and availability. But as the market moves toward assemblies, you need to know what to look for in a partner.

Absolutely. The industry is rapidly moving from "selling tires" to "delivering ready-to-install wheel solutions11." This redefines the supplier's role from a simple parts vendor to an integrated assembly12 and logistics2 partner who adds value far beyond the product itself.

The future of this business isn't just about having good tires. It's about having the capability to be a true solutions provider. A modern supplier needs more than just a tire catalog; they need engineering expertise13 to ensure proper fitment, assembly lines to produce consistent quality, and a flexible supply chain14 to deliver ready-to-install products just in time. This is a huge part of our philosophy at Gescomaxy. We offer free assembly services and can ship mixed containers of different assemblies because we understand our customers aren't just buying parts anymore. They are buying efficiency. They are buying the elimination of a problem. Suppliers who only ship tires will be left behind, while those who can deliver a complete, guaranteed, and ready-to-use wheel assembly will become essential partners to OEMs and large dealers.

Conclusion

The shift to complete wheel assemblies1 isn't a trend; it's a logical evolution. It reduces risk, simplifies logistics2, and ensures performance3, turning a component purchase into a reliable, integrated solution.

Explore how complete wheel assemblies can enhance performance and reliability in your operations. ↩

Learn about the role of logistics in ensuring timely and efficient delivery of wheel assemblies. ↩

Learn how complete wheel assemblies can enhance overall performance and reliability in machinery. ↩

Understand the common causes of bead sealing failures and how to prevent them for better tire performance. ↩

Find out how torque mismatch can lead to inefficiencies and damage in tire and rim systems. ↩

Discover the impact of uneven wear on tire longevity and performance, and how to avoid it. ↩

Explore the concept of single-point accountability and its benefits in procurement and assembly processes. ↩

Learn about the importance of OEM-level standards for ensuring quality and compatibility in wheel assemblies. ↩

Learn about the significance of verified compatibility in ensuring seamless integration of wheel components. ↩

Explore the methods used to ensure quality assurance in the assembly of wheels and tires. ↩

Learn about the advantages of ready-to-install wheel solutions for efficiency and reliability. ↩

Understand the advantages of integrated assembly in enhancing product reliability and performance. ↩

Discover how engineering expertise can improve fitment and overall performance in tire supply. ↩

Discover how a flexible supply chain can enhance responsiveness and efficiency in tire manufacturing. ↩