You’re tired of your tire costs1 fluctuating wildly with the natural rubber market. This unpredictability makes budgeting impossible and eats into your profits, leaving you feeling helpless.

The shift to synthetic rubber, like S-IR, is creating more stable pricing and predictable supply chain2s. It also allows for highly-tuned compounds that offer specific performance benefits, like better wear resistance3 or lower fuel consumption4.

I remember a few years back, a big client, a purchasing manager for an agricultural cooperative, called me in a panic. Natural rubber prices had just spiked nearly 30% in a quarter because of bad weather in Southeast Asia. His annual budget was completely blown. He asked me, "Isn't there a way to get off this roller coaster?" That conversation really highlighted the problem we were all facing. It’s why my team and I doubled down on our synthetic rubber compound development5. We knew that offering stability was just as important as offering a good price. This shift isn't just about chemistry; it's about giving control back to our clients.

How Can Synthetic Rubber Stabilize Your Tire Costs?

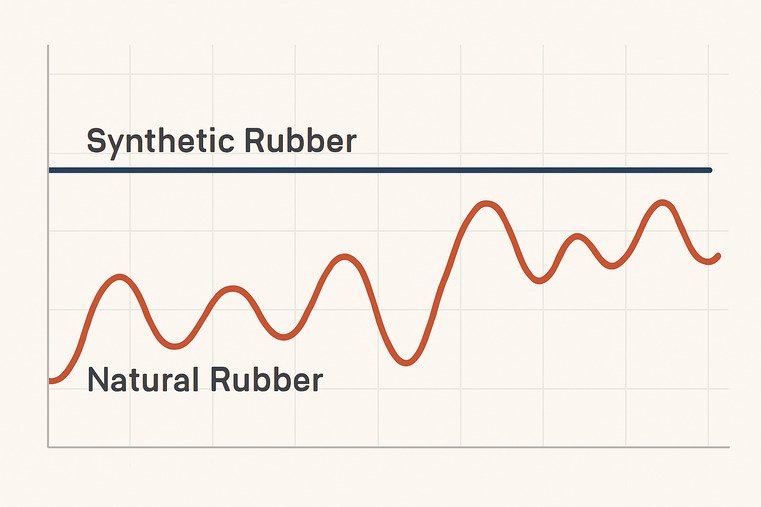

You watch natural rubber prices6 go up and down like a yo-yo. This volatility from weather and politics overseas makes it impossible to plan your procurement budget with any certainty.

Synthetic rubber, especially Synthetic Isoprene Rubber (S-IR)7, decouples tire costs1 from the volatile agricultural commodity market. Its production is based on more stable industrial inputs, offering predictable pricing8 and a secure supply chain2.

The core issue with natural rubber (NR) is that over 90% of it comes from just a few countries in Southeast Asia. The supply is vulnerable to everything from bad weather and crop disease to local politics and labor issues. This creates constant price shocks. As a buyer, you feel this directly. One day a tire costs1 X, the next it's X plus 20%. Synthetic rubber (SR) changes this dynamic completely. It's an industrial product, primarily derived from petroleum. While oil prices can fluctuate, they are far more predictable and less volatile than the day-to-day NR market. For my clients, this means we can offer long-term price agreements and reliable delivery schedules. You are no longer gambling on the weather half a world away. This shift gives you, the buyer, the power to forecast your costs accurately and manage your inventory with confidence.

Sourcing & Cost: Natural vs. Synthetic Rubber

| Feature | Natural Rubber (NR) | Synthetic Rubber (S-IR) |

|---|---|---|

| Source | Agricultural crop (rubber trees) | Industrial process (from petroleum) |

| Geography | Concentrated in Southeast Asia | Diverse global production |

| Vulnerabilities | Weather, disease, geopolitics | Oil price fluctuation |

| Price Stability | Low (highly volatile) | High (relatively stable) |

| Benefit for Buyer | Traditional performance | Budget predictability, supply security |

Can a Tire Really Be Both Durable and Fuel-Efficient?

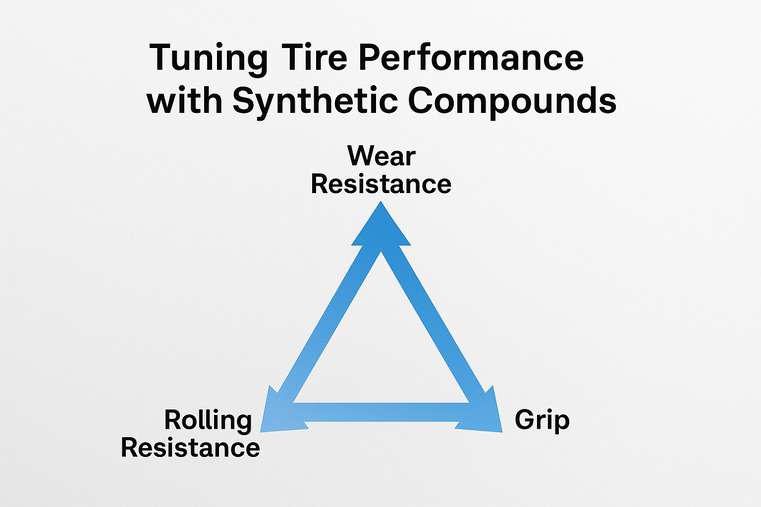

You've always been told it's a trade-off. A tough, long-lasting tire will have high rolling resistance9 and burn more fuel. A fuel-efficient tire will be softer and wear out quickly.

Yes. Modern synthetic compounds allow for precise "tuning." By mixing different synthetic polymers and additives, we can break the old compromises and engineer a tire that delivers both long service life and excellent rolling resistance9.

In the past, this trade-off was a real limitation of natural rubber compounds. You had to choose one primary benefit at the expense of another. But with synthetic rubber, we can work like master chefs adjusting a recipe. We can blend different types of synthetic rubber (like S-IR and Butadiene Rubber) and use specific silica fillers to fine-tune the final properties. For example, for a large mining truck, the client's main concern is preventing cuts and extending wear life in a very abrasive environment. Here, we would engineer a compound focused on maximum toughness. For an agricultural tractor that spends a lot of time on the road moving between fields, the client wants to save fuel. In this case, we can tune the compound for lower rolling resistance9, while still maintaining good durability. It’s no longer an "either/or" choice. I can now ask my clients, "What is your biggest operational challenge?" and then deliver a tire specifically compounded to solve it.

Tuning Compounds for Your Application

| Application | Primary Need | Compound Tuning Focus | Resulting Benefit |

|---|---|---|---|

| Mining Haul Truck | Durability & Cut Resistance | High-hysteresis, tough polymers | 30% longer service life |

| Agricultural Tractor | Fuel Economy & Soil Protection | Low-hysteresis, flexible polymers | 5-7% reduction in fuel use |

| Port Straddle Carrier | Load Capacity & Stability | Stiff compound, reinforced structure | Higher load rating, less sway |

How Do You Translate Lab Jargon into Real-World Value?

A supplier sends you a spec sheet full of terms like "Shore A Hardness," "tensile strength," and "rebound resilience." You know it's important, but you have no idea what it means for your fleet.

A good supplier doesn't just sell you a tire; they translate technical specifications10 into tangible business outcomes. They should explain how a specific compound property will lower your cost-per-hour11 or increase your operational uptime12.

My role is to be a bridge between our engineers' lab and your real-world operations. It’s my job to make the technical simple. When our lab develops a new compound with "improved tear strength," I don't tell my client that. Instead, I say, "This new tire is much more resistant to damage from sharp rocks, which means you'll have fewer sudden failures and more uptime in your quarry." When we create a compound with "lowered hysteresis," I explain it as, "This tire wastes less energy as it rolls, which will directly reduce your fuel bill." The specifications are proof, but the benefits are what matter to your business. I always make sure our discussions are about your goals: reducing downtime, cutting fuel costs, or extending replacement cycles. The technical data just shows how we get you there.

The Buyer-Friendly Translation Guide

| Technical Term | What It Really Means | The Bottom-Line Benefit for You |

|---|---|---|

| High Tensile Strength | The rubber is very hard to pull apart. | Resists cuts and punctures, leading to fewer failures. |

| Low Rolling Resistance | The tire wastes less energy as it flexes. | Improves your vehicle's fuel efficiency, saving money. |

| High Shore A Hardness | The rubber is hard and resists deformation. | Better for carrying very heavy loads and longer wear on smooth surfaces. |

| Good Rebound Resilience | The rubber bounces back well after being compressed. | Indicates lower rolling resistance9 and less heat buildup. |

Conclusion

The shift to synthetic rubber gives you stable costs and superior performance. Partner with a supplier who translates complex science into real-world value, solving your biggest operational challenges.

Discover how synthetic rubber can help you manage and predict tire costs effectively. ↩

A stable supply chain can ensure timely delivery and consistent pricing for your tire needs. ↩

Understanding wear resistance can help you choose tires that last longer and perform better. ↩

Explore the relationship between tire materials and fuel efficiency for cost savings. ↩

Learn about innovations in synthetic rubber that enhance tire performance and cost stability. ↩

Understanding the factors behind natural rubber price volatility can help you make informed decisions. ↩

Explore how S-IR can provide stability in pricing and performance for your tire needs. ↩

Find out how predictable pricing can improve your budgeting and financial planning. ↩

Understanding rolling resistance can help you select tires that optimize fuel economy. ↩

Learn how to interpret technical specs to make better tire purchasing decisions. ↩

Understanding these factors can help you reduce overall operational costs. ↩

Discover how the right tires can minimize downtime and enhance productivity. ↩