You see general reports on the agricultural market, but you need specific data on irrigation tires. Without it, you're just guessing where to focus your inventory and sales efforts.

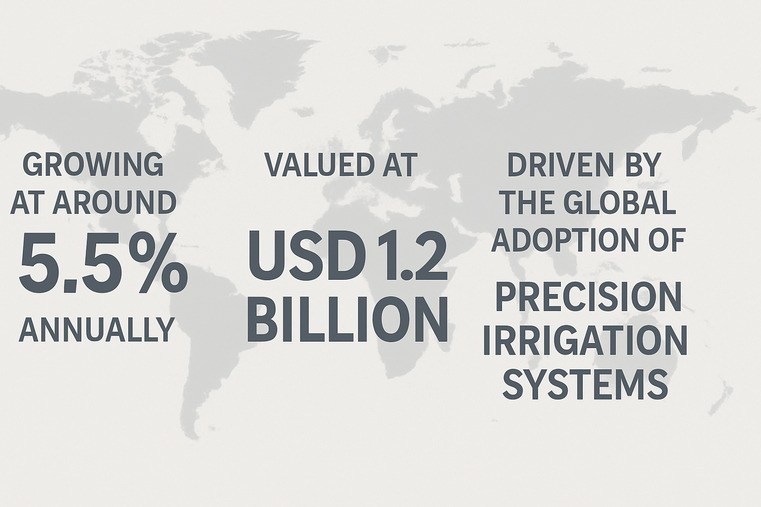

The irrigation tire market1 is growing at around 5.5% annually, outpacing the broader agricultural tire market2. Valued at about USD 1.2 billion, this growth is driven by the global adoption of precision irrigation systems3.

I remember talking with a distributor from a water-scarce region a few years ago. He was focused entirely on large tractor tires. I showed him the data on how investment in center-pivot irrigation was booming in his country. He was skeptical, seeing irrigation tires as a low-margin, niche product. I convinced him to stock a small container as a trial. Within six months, he called me back to place a much larger order. He saw firsthand that while everyone else was fighting over the tractor tire market, a huge, underserved need was growing right under his nose. The market isn't just about tractors anymore; it's about the entire ecosystem of modern farming.

What’s Fueling This Above-Average Growth?

You see the 5.5% growth number, but is this a temporary spike or a long-term trend? You need to understand the forces behind the numbers before you commit your capital.

This growth is a long-term trend, fueled by the non-negotiable global need to produce more food with less water. Mechanized center-pivot and linear irrigation systems are the most effective solution, directly driving tire demand4.

The core driver here is simple necessity. The world needs more food, but many key farming regions are facing severe water shortages. Old methods like flood irrigation are incredibly wasteful. This is forcing a massive shift toward precision irrigation, like center-pivot and linear move systems. These machines can be massive, sometimes half a mile long, and they roll on dozens of tires. Every new system installed represents a direct sale of 10, 20, or even more tires. This isn't a choice for farmers; it's a matter of survival and efficiency. For us in the tire trade, it means this niche segment is tied to one of the most fundamental trends in modern agriculture: water conservation and mechanization. It's a reliable, growing demand you can build a business on.

Key Drivers of the Irrigation Tire Market

| Driving Force | Impact on the Market | Why It Matters to You |

|---|---|---|

| Water Scarcity | Farmers must adopt water-efficient methods. | Creates sustained, non-negotiable demand for pivot systems and their tires. |

| Global Mechanization | Need for higher efficiency and lower labor costs. | Every new mechanized system is a guaranteed sale of multiple tires. |

| Increased Crop Yields | Precision irrigation delivers water and nutrients effectively. | Farmers see a clear return on investment, encouraging further adoption. |

Why Can’t You Just Use a Standard Farm Tire?

You might think any small agricultural tire will do for an irrigation system. This seems like a chance to use up old stock or buy the cheapest option available to save money.

Standard tires will fail. Irrigation tires are specially designed with non-directional, shallow treads5 and UV-resistant compounds6 to handle constant slow movement, wet conditions, and sun exposure without damaging crops or getting stuck.

Using a standard tractor tire on a pivot system is a classic mistake I see all the time. A tractor tire is designed for high traction, with deep lugs that dig into the soil. On a pivot system, this deep tread will dig ruts, get stuck in the mud, and damage the shallow roots of the crops. It's the wrong tool for the job. Irrigation tires, on the other hand, have a very different design philosophy. The tread is shallow and often non-directional, designed to float on top of the wet soil rather than dig in. Furthermore, the rubber compound itself is different. These tires sit out in the sun, unmoving for long periods, so they need advanced UV and ozone inhibitors to prevent cracking and premature failure. It's a specialized product for a specialized task. Trying to cut corners here only leads to crop damage and costly system downtime for your customers.

Irrigation vs. Tractor Tires: The Right Tool for the Job

| Feature | Irrigation Tire | Standard Tractor Tire |

|---|---|---|

| Tread Design | Shallow, non-directional | Deep, directional lugs |

| Primary Function | Float on wet soil, minimize crop damage | Maximize traction and pull |

| Movement | Slow, constant, or stationary | Variable speed, high torque |

| Rubber Compound | High UV and ozone resistance | High wear and cut resistance |

| Result of Misuse | Crop damage, rutting, system failure | N/A |

Conclusion

The irrigation tire market1 is growing fast due to global needs for food and water efficiency. Understanding this niche and its specific product requirements offers a significant, stable growth opportunity.

Explore this link to gain insights into market trends and opportunities in the irrigation tire sector. ↩

Get insights into the broader agricultural tire market and its growth potential. ↩

Learn about the benefits of precision irrigation systems and their role in modern farming. ↩

Explore the factors influencing tire demand in the agricultural market for better inventory decisions. ↩

Discover how shallow treads benefit irrigation tires and prevent crop damage. ↩

Understand the importance of UV-resistant compounds in tire longevity and performance. ↩