You’ve sourced a batch of OTR tires that perform perfectly, but the next shipment has issues. This inconsistency is frustrating and risks damaging your brand’s reputation with every unpredictable failure.

Consistency in OTR tire manufacturing1 is difficult because, unlike mass-produced car tires, OTR tires are largely hand-built2. This reliance on manual processes like ply laying3 and batch curing4 introduces human variability5, making it challenging to replicate the exact same tire every single time.

Over my 13 years in this industry, I’ve visited countless factories. The difference between a passenger car tire (PCR) plant and an OTR plant is staggering. The PCR factory is a sea of robotics and high-speed automation, churning out identical tires every few seconds. In contrast, the OTR factory floor is a workshop where skilled technicians meticulously build each tire. This hands-on process is both a strength—allowing for complex, robust designs—and the root cause of the consistency challenge that every procurement manager faces. Understanding this fundamental difference is the first step to building a more reliable supply chain.

Why can't OTR tire factories be fully automated like car tire factories?

You see the incredible consistency of automotive tires and wonder why OTR suppliers can't just adopt the same technology. It seems like a straightforward solution to a frustrating problem.

Full automation for OTR tires is economically and technically impractical due to their massive size, heavy components, and low-volume production. The required machinery would be enormous, prohibitively expensive, and lack the flexibility needed for the high-mix nature of OTR manufacturing.

I've had this conversation many times with procurement managers. They push for automation, thinking it's the silver bullet for consistency. But the reality is, the business case just isn't there. A factory might produce 20,000 car tires in a day, but only 50 giant loader tires. You can't justify a multi-million dollar robot to build a few dozen units. The sheer weight and unwieldy nature of the components—like steel belts that weigh hundreds of pounds—require a level of precision and dexterity that is still best handled by skilled human hands. The process is less like an assembly line and more like craftsmanship, where expertise is paramount.

The Economics and Engineering of Automation

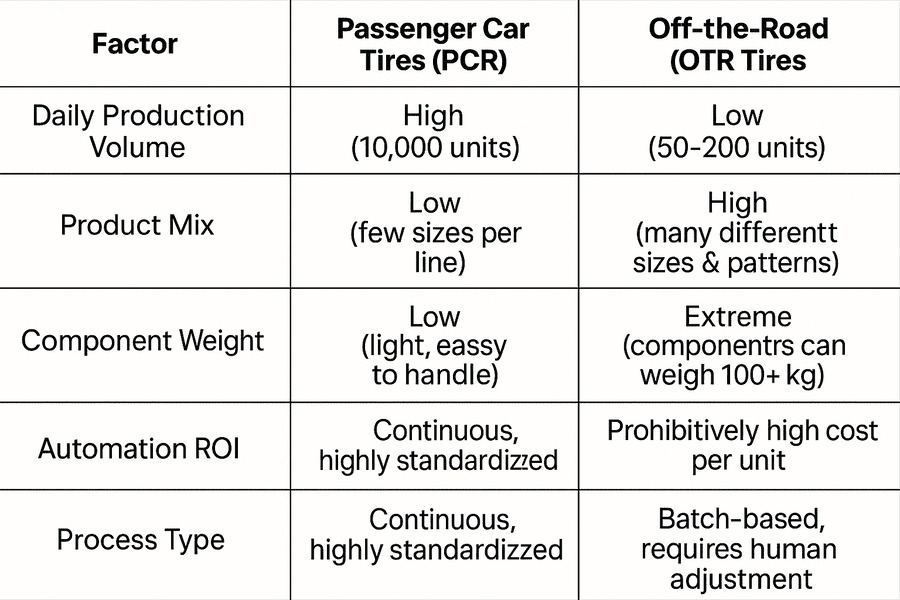

The decision against full automation isn't about a lack of will; it's a practical response to the unique demands of the OTR market. A direct comparison with passenger car tire production makes the reasons crystal clear.

| Factor | Passenger Car Tires (PCR) | Off-the-Road (OTR) Tires |

|---|---|---|

| Daily Production Volume | High (10,000+ units) | Low (50-200 units) |

| Product Mix | Low (few sizes per line) | High (many different sizes & patterns) |

| Component Weight | Low (light, easy to handle) | Extreme (components can weigh 100+ kg) |

| Automation ROI | High (costs spread over millions of units) | Low (prohibitively high cost per unit) |

| Process Type | Continuous, highly standardized | Batch-based, requires human adjustment |

This fundamental difference means OTR manufacturing will always depend on human skill to bridge the gap that automation cannot fill.

How does the "hand-built2" process create specific inconsistencies?

You know production is manual, but you don’t know where the problems actually start. This makes it impossible to ask a supplier the right questions about their quality control.

Inconsistencies arise from specific manual steps. Minor variations in ply tension, the precision of the tread splice, and slight fluctuations in temperature during batch curing4 can all impact the tire’s final balance, durability, and performance.

I remember inspecting a batch of tires where we saw unusual balance issues. After a deep dive with the factory's engineers, we traced the problem back to a single operator on the building machine who was applying slightly uneven tension to the plies. It was a tiny, almost imperceptible difference, but on a large OTR tire, it was enough to affect performance. This isn't about a lack of care; it's about the inherent limits of human precision. Every single step, from applying the first layer to joining the tread, is a potential point of variation that a good supplier must meticulously control through training and rigorous inspection.

Critical Manual Touchpoints and Their Impact

To manage consistency, you need to know where to look. The entire process is hands-on, but three areas are particularly critical for quality control.

- Ply Laying & Tension: Technicians wrap layers of fabric or steel cord around the tire drum by hand. If the tension is uneven or the overlap between layers is inconsistent, it can create weak spots or structural imbalances in the final tire. This can lead to uneven wear or even catastrophic failure under heavy load.

- Tread Splicing: The tread is applied as a long strip and the two ends must be joined together perfectly. An imprecise cut or a poorly joined splice creates a weak point. This is often where tread separation issues begin, especially in high-torque applications.

- Batch Curing: Unlike the continuous flow of a PCR factory, OTR tires are cured in individual presses. Minor variations in loading time, press temperature, or pressure can lead to tires being slightly over-cured or under-cured, affecting both wear life and durability. A good supplier will have automated monitoring on their presses to minimize these variables.

How can you verify a supplier's consistency?

You're tired of surprises and need a reliable way to vet suppliers. Simply trusting a factory's sales pitch isn't enough when your brand reputation is on the line.

You can verify consistency by reviewing their quality control systems6, specifically their process for data tracking7 and traceability8. A reliable supplier will have a system, like individual tire barcodes, to trace any tire back to its exact production data.

When I visit a potential partner factory, I don't just look at the tires; I ask to see their data. At Gescomaxy, every single tire gets a unique barcode. We can scan it and instantly pull up every piece of data: the rubber batch used, the curing press temperature and time, and the results from over 30 inspection points, including balance and X-ray tests. This level of traceability8 is non-negotiable for us. If a supplier can't show you this level of detailed, systematic tracking for every single tire, they cannot guarantee consistency. It's that simple.

A Checklist for Verifying Supplier Consistency

Ask your potential suppliers these questions. Their answers will reveal the true strength of their quality systems. A confident "yes" to all of these is a strong indicator of a reliable partner.

| Verification Point | What to Look For | Why It Matters |

|---|---|---|

| Material Testing | Do they test every batch of raw rubber, steel, and fabric? | Garbage in, garbage out. Consistency starts with consistent raw materials. |

| Process Controls | Are critical steps like curing automated and monitored? | This removes human error from key processes that affect durability and performance. |

| 100% Final Inspection | Do they inspect every single finished tire, not just a sample? | Sampling is not enough for OTR tires. You need to know every tire was checked for defects. |

| Individual Traceability | Can they provide a full production report9 for a single tire using a serial number? | This is the ultimate proof of a robust quality system and a commitment to accountability. |

Without these systems in place, a supplier is relying on luck, not process, to achieve consistency.

Conclusion

Achieving OTR tire consistency requires overcoming the challenges of manual production through rigorous, data-driven quality control and complete traceability8 from raw material to the final product.

Explore the complexities of OTR tire manufacturing and understand the unique challenges faced in production. ↩

Discover the reasons behind the hand-built process of OTR tires and its impact on quality. ↩

Understand the critical ply laying process and its significance in tire quality. ↩

Explore the batch curing process and its effects on tire performance and durability. ↩

Learn how human variability influences the consistency and quality of tire production. ↩

Discover best practices in quality control systems that ensure tire consistency. ↩

Explore how data tracking enhances quality assurance in tire production. ↩

Understand the significance of traceability in ensuring tire quality and accountability. ↩

Understand the essential elements of a production report for tire traceability. ↩