You demand tires made last month, creating supply chain headaches. This wastes time and you worry you're getting "old" stock. It is a frustrating and unnecessary cycle for everyone involved.

Because newly produced tires have not yet reached their peak performance. They need an 8–12 month stabilization period1 for their internal structure to settle. Properly stored tires remain safe and perform optimally for years, making storage conditions more critical than the production date.

I'll never forget a new procurement manager who rejected an entire container of perfectly good OTR tires. His reason? They were manufactured 10 months ago. He proudly told me he only accepted tires produced within the last six months. He thought he was being diligent and protecting his company. In reality, he was turning away a product that was just entering its prime performance window and accepting tires that were still "green." This common misunderstanding doesn't increase safety; it just creates logistical nightmares2 and opens the door to other, more serious risks. Let's break down why this obsession with "freshness" is misguided.

Aren't Newer Tires Safer and Better Performing?

You believe a tire made last week must be better than one made last year. This assumption makes you reject older stock, even if it comes from a trusted supplier, because you fear it's already degraded.

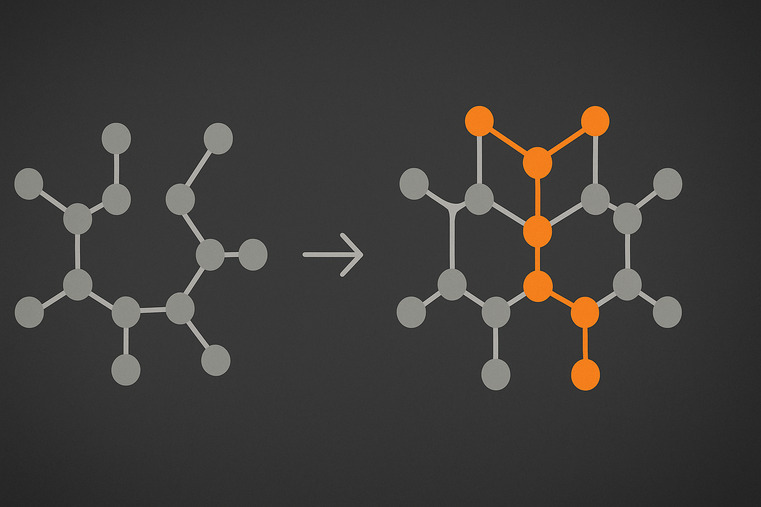

No, they are not. A brand-new tire's internal chemical structure3 is still settling. A tire that has been properly stored for 8-12 months has completed this process, giving it superior strength, durability, and wear resistance over a "fresh" one.

Think of a high-quality tire like a fine wine or a cured cheese—it gets better with a little age. The manufacturing process involves heating various materials like rubber, carbon black, and chemicals. After the tire is molded, these components continue to cross-link and bond on a molecular level. This is called the stabilization or curing period. It can take up to a year for this process to complete fully. A tire used too soon, before it is fully stabilized, can wear faster and be less resistant to damage. In our warehouse, we know that a tire sitting in a cool, dark, climate-controlled environment for a year is not "aging"; it's "maturing." Global manufacturers like Michelin have confirmed that a tire's service life begins when it's installed on a vehicle, not when it's made. A 3-year-old, properly stored tire is for all practical purposes a new tire, often with better-stabilized properties than one fresh from the factory.

Tire Performance: Fresh vs. Matured

| Feature | "Fresh" Tire (0-6 Months) | Matured Tire (8-24 Months) |

|---|---|---|

| Chemical Structure | Unsettled, still cross-linking | Fully stabilized and bonded |

| Wear Resistance | Sub-optimal | Optimal |

| Durability | Good | Peak |

| Overall Performance | Good, but not at its best | At its peak potential |

If Fresher Isn't Better, Why Does Everyone Demand It?

You feel pressure from your customers or management to source the newest tires possible. This demand seems logical, but it clashes with what your most experienced suppliers are telling you, creating confusion and mistrust.

Because this widespread myth creates a business opportunity for fraudsters. Unscrupulous sellers exploit this obsession by illegally tampering with date codes, selling you a dangerously old tire disguised as a "fresh" one, which is far riskier than a properly stored inventory tire.

The market's obsession with production dates has created a dangerous side effect: fraud. Because buyers are willing to pay more or exclusively buy "fresh" tires, it incentivizes dishonest brokers to alter the DOT (Department of Transportation) date codes. I have personally seen old, improperly stored tires4 that were cracked and hardened get a new, "fresh" date code stamped on them. A buyer who thinks they are getting a 3-month-old tire is actually getting an 8-year-old safety hazard. This is infinitely more dangerous than buying a legitimate 3-year-old tire that has been stored correctly by a reputable dealer. The major, world-class brands know this. Companies like Continental and Michelin have published official statements debunking the "fresher is better" myth, emphasizing that storage and maintenance are what count. The irrational demand for freshness doesn't increase safety; it fuels a black market5 that actively compromises it.

So, What Really Determines a Tire's Lifespan?

You're focused on the production date as the key indicator of a tire's health. But you still see tires fail prematurely, leaving you wondering what you're missing and what you should really be tracking.

A tire's real life is determined by use, not its age in a warehouse. Factors like driving habits6, impact damage, maintaining proper tire pressure7, correct alignment, and regular maintenance routines8 have a far greater impact on safety and longevity.

The moment a tire is mounted on a vehicle and put into service, its life truly begins. From that day forward, several factors will determine its lifespan far more than its birthday. Is the tire constantly underinflated, causing it to overheat and wear unevenly? Is the vehicle's alignment off, causing rapid shoulder wear? Is the operator driving aggressively, hitting curbs, or driving over damaging debris? These are the questions that matter. A tire that is one year old but has been run with low pressure for 10,000 miles is in much worse condition than a five-year-old tire that has just been installed and is properly maintained. Focusing on the DOT code is like judging a person's health by their birth certificate instead of their lifestyle. To ensure safety and maximize your investment, shift your focus from the factory production date to a strict, disciplined schedule of in-service maintenance and inspection.

Conclusion

Stop asking for "fresh" tires and start demanding properly stored and maintained tires. A tire's true value lies in its condition and care, not the date it was manufactured.

Understanding the stabilization period can help you make informed decisions about tire purchases and safety. ↩

Explore the challenges in tire procurement to better navigate your supply chain. ↩

Explore the science behind tire chemistry to understand why age matters more than you think. ↩

Learn how storage conditions impact tire longevity and performance, ensuring safer driving. ↩

Discover the risks of the black market in tires and how to protect yourself. ↩

Understand how your driving style can affect tire wear and safety. ↩

Learn the importance of tire pressure in preventing accidents and extending tire life. ↩

Implementing proper maintenance routines can significantly enhance tire performance and safety. ↩