You see an expensive OTR tire fail with shoulder cracks or tread separation, long before its expected lifespan. The failure seems random, creating warranty headaches and damaging your operational budget.

Green tire uniformity1 is critical because it ensures the tire’s internal structure is perfectly balanced before it's cured. Even millimeter-level misalignments in plies or belts create hidden stress points, leading to concentrated heat and force that destroy the casing under heavy loads.

I've walked through dozens of tire factories over the past 13 years, and the most critical area is often the quietest: the tire building department2. This is where the tire is born. Before it's a tough, black OTR tire, it’s a soft, floppy, and delicate "green tire." I once watched two builders working side-by-side. One followed his standard operating procedure3 (SOP) to the letter, checking every alignment. The other rushed a few steps to finish faster. Their green tires looked almost identical. But I knew that one was built to last 2,000+ hours, and the other was destined for a premature death.

What Exactly is a "Green Tire" and Why is its Uniformity so Fragile?

The term "green tire" can be misleading. It has nothing to do with color. But overlooking this stage means you miss the root cause of many catastrophic casing failures4 down the road.

A "green tire" is the fully assembled but uncured tire. Its uniformity refers to the perfect alignment and tension of all its components—plies, belts, and beads. This stage is incredibly fragile because the materials are soft, and small human or machine errors are easily locked in.

Think of building a tire like laying the foundation for a skyscraper. If one steel beam is slightly out of place on the first floor, the entire structure becomes unstable as you build higher. The green tire is that foundation. It's constructed by wrapping multiple layers of rubber, fabric, and steel around a drum. If the tension on a ply is uneven, or a belt is off by just a few millimeters, that defect gets permanently "baked in" during curing. This is why a factory's discipline and SOPs during tire building are a direct indicator of their final product's field performance. A small error here has massive consequences under heavy loads.

The Anatomy of a Green Tire Failure

These four errors in the building stage are the primary culprits behind casing failures4.

| Building Error | What Goes Wrong | Consequence Under Load |

|---|---|---|

| Variable Ply Tension | One side of a ply is stretched tighter than the other. | Creates an imbalanced force, leading to uneven wear and pulling. |

| Misaligned Splices | The seams of the plies or belts overlap or have gaps. | Creates a stiff or weak spot that causes vibrations and separations. |

| Non-Concentric Beads | The steel bead bundles are not perfectly centered on the drum. | Causes the tire to mount improperly, leading to high vibration and bead failure. |

| Shifted Belt Angles | The steel belts shift, changing their precise angle. | Drastically compromises the casing's strength and stability. |

How Do These Tiny Imbalances Lead to Major Failures?

A tire might pass final inspection for balance, but that doesn't mean its internal structure is sound. How can a millimeter of misalignment lead to a tire shredding itself apart in the field?

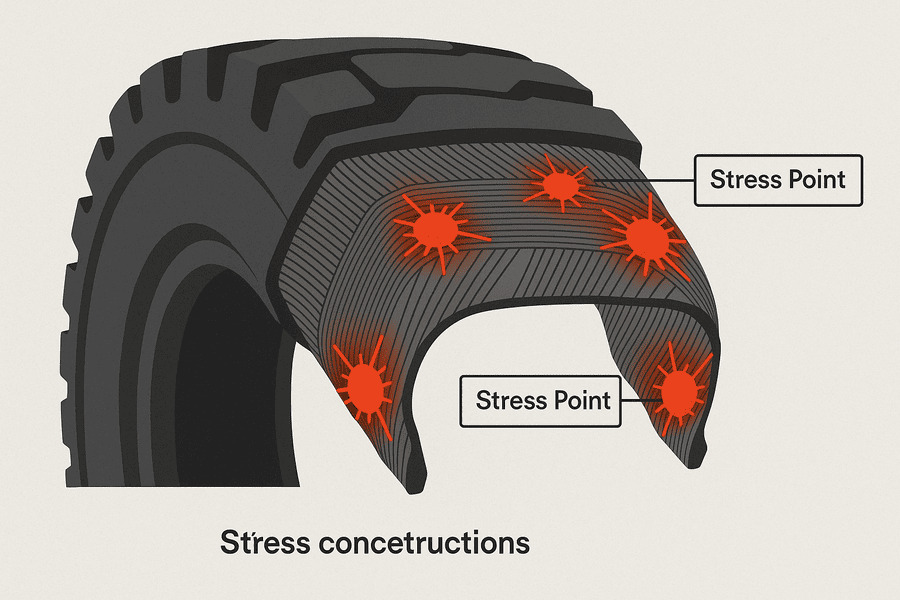

These tiny imbalances create concentrated stress points. Under heavy loads, these points generate immense heat and are subjected to repeated, uneven forces. This leads to higher heat generation5, shoulder cracking, and eventually, the layers of the tire separating.

I often use this analogy with clients: imagine you have two people trying to lift a heavy weight. If they lift in perfect sync, they can handle it. But if one person lifts a split-second before the other, all the force momentarily goes to one person, risking injury. An imbalanced tire casing is the same. When a misaligned splice or a tighter ply section rotates under load, it takes on more force and generates more friction and heat than the areas around it. This localized heat weakens the rubber's chemical bonds. Over thousands of cycles, that weak spot grows, a crack forms, and the tire's layers begin to peel apart. This is why strict SOPs and builder consistency are non-negotiable for a reliable OTR tire.

The Domino Effect of Poor Uniformity

A single green tire error triggers a chain reaction that leads to failure.

- Initial Imbalance: A misaligned ply or belt creates an uneven distribution of mass and stiffness.

- Heat Concentration: As the tire flexes under load, this spot generates more friction and heat than the surrounding areas.

- Material Degradation: The excess heat begins to break down the rubber compound and the adhesion between layers.

- Crack Formation: A small crack begins to form at the high-stress point, often at the shoulder or belt edge.

- Catastrophic Failure: The crack rapidly grows, leading to tread separation or a complete casing blowout.

How Can You Ensure Your Supplier is Delivering Uniform Green Tires?

You can't personally inspect every green tire. So, how can you be sure that your supplier isn't shipping you a hidden problem? The proof is in their process control and inspection data.

Ensure uniformity by auditing your supplier's tire building SOPs and their green tire inspection process. A top-tier supplier uses laser-guided systems and conducts regular uniformity checks on uncured tires, not just the final product, to catch deviations early.

When we vet a new manufacturing partner at Gescomaxy, we don't just look at their final inspection machines. We spend time at the building stations. Do they use laser guides to ensure perfect centering and alignment? How often are builders retrained on SOPs? Do they pull green tires off the line for analysis? A reliable factory has a culture of "zero deviation" at this stage. They have systems in place to minimize human variability, like standardized splice placement and automated tension controls. Ask your supplier to walk you through their green tire quality gates. If they can't show you rigorous, documented controls at this stage, they can't guarantee casing integrity.

Your Green Tire Uniformity Checklist

Demand evidence of these controls from your supplier.

| Control Point | What to Ask For | Why It's Non-Negotiable |

|---|---|---|

| Builder SOPs | "Show me your documented SOPs for tire building and your training records." | Proves they have a standardized process to reduce human variability. |

| Alignment Technology | "What technology, like laser guides, do you use to ensure belt and bead centering?" | Manual alignment is prone to error. Technology ensures precision. |

| Green Tire Audits | "What is your process for inspecting green tires before they are cured?" | This catches errors early, proving they are proactive, not reactive, about quality. |

Conclusion

The durability of an OTR casing is determined before it's even cured. Partnering with a supplier who obsesses over green tire uniformity is the only way to prevent unpredictable casing failures4.

Understanding green tire uniformity is crucial for ensuring tire longevity and performance, making this resource invaluable. ↩

Explore the tire building department's role in tire quality to appreciate the complexities of tire manufacturing. ↩

Learn about SOPs in tire manufacturing to understand how they ensure quality and consistency. ↩

Discover the root causes of casing failures to better understand tire durability and maintenance. ↩

Learn about the effects of heat generation on tire longevity to make informed decisions about tire care. ↩