You invest in a premium batch of OTR tires, but one fails at 1,000 hours while another is still going strong at 2,000. This unpredictable performance makes budgeting impossible and damages your credibility.

Curing stability1 is the final, critical step that locks in a tire's durability. Even tiny deviations in heat or pressure create invisible weaknesses that can cut a tire's potential 2,000+ hour lifespan in half, causing premature failure from heat buildup or cracking.

I once had a client, a procurement manager2 for a large mining operation, who was facing this exact problem. He said, "It feels like a lottery. The tires all look identical, but they perform so differently." He was right to be frustrated. The answer wasn't visible on the tread or sidewall. The secret to a tire's longevity is forged under intense heat and pressure in a process called curing. This is where a seemingly perfect "green tire" is either transformed into a durable workhorse or a ticking time bomb.

What Exactly Happens During the Tire Curing Process?

Curing is often treated like a "black box" in manufacturing. The tire goes in soft and comes out hard. But not understanding this stage means you can't identify a key source of quality risk.

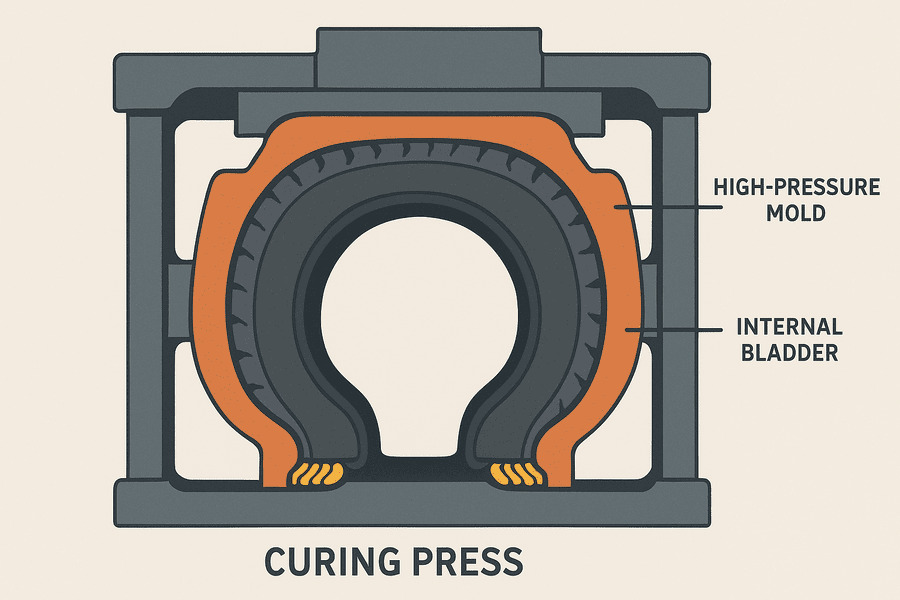

Curing, or vulcanization3, uses a high-pressure mold and an internal bladder to apply heat (around 150°C) for 2 to 6 hours. This process creates strong chemical cross-links in the rubber, transforming it from a soft, pliable material into a strong, elastic, and durable final product.

Think of it like baking a cake. You can have the best ingredients (the rubber compound), but if your oven temperature is off or you take it out too early, the result is a disaster. OTR tire curing is far more complex. Due to the tire's massive size and thickness, getting heat to penetrate evenly is a huge challenge. The process is long, and every minute is critical. A supplier who doesn't have absolute control over this stage cannot produce a consistently reliable tire. It's the most difficult part of the process to stabilize and the most critical for performance.

OTR Curing vs. Car Tire Curing

The scale of OTR tire curing makes it much more sensitive to error.

| Feature | OTR Tire Curing | Passenger Car Tire Curing |

|---|---|---|

| Cycle Time | 2 – 6 hours | 10 – 15 minutes |

| Tire Mass | Extremely heavy and thick | Light and thin |

| Heat Transfer | Slow, high risk of unevenness | Fast and relatively uniform |

| Impact of Error | Drastic reduction in lifespan | Often minor cosmetic or balance issues |

This complexity is why curing stability is a key differentiator between average and top-tier OTR tire suppliers.

How Do Small Curing Variations Ruin a Tire's Performance?

A tire comes out of the press looking flawless. It passes visual inspection. But three months later, it's failing in the field, costing you downtime and warranty claims. What went wrong?

Tiny changes in curing create major performance differences. Under-curing makes rubber weak and prone to heat failure. Over-curing makes it brittle and easy to crack. Uneven mold temperatures also cause inconsistent tread hardness, leading to rapid, uneven wear.

This is the hidden reason for the 1,000-hour vs. 2,000-hour performance gap. A tire that's slightly under-cured can't dissipate heat properly. Under a heavy load, its internal temperature skyrockets, the rubber weakens, and you get a catastrophic separation. Conversely, an over-cured tire might look tough, but its rubber has lost elasticity. The first significant impact or flex can cause a deep crack. These aren't visible defects; they are fundamental flaws in the rubber's molecular structure, all because the "baking" process wasn't perfect.

The Three Deadly Sins of Curing

These three failures are directly responsible for turning a good tire into a liability.

- Under-curing: The chemical reaction is incomplete. The rubber is too soft, leading to high heat buildup, fast wear, and potential tread separation. The tire essentially melts from the inside out.

- Over-curing: The rubber is "over-baked" and becomes brittle. This reduces its ability to flex, resulting in cracks forming in the sidewall or at the base of the tread grooves.

- Uneven Heating: If one part of the mold is slightly cooler, that section of the tire will be under-cured. This creates hard and soft spots in the tread, causing bizarre and rapid wear patterns.

How Can You Guarantee Your Supplier Has Stable Curing?

You can't stand by the curing press 24/7. So how do you protect your investment and ensure every tire you buy is properly cured? The answer lies in data and traceability4.

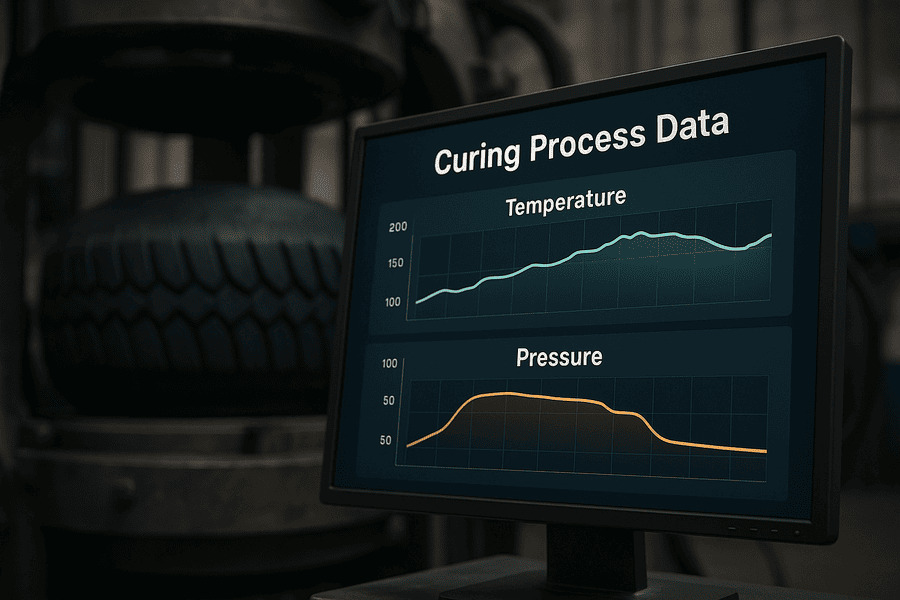

To guarantee stability, demand that your supplier provides curing data5—temperature and pressure logs6—for each production batch. A trustworthy partner links this data to every tire's unique serial number, creating a transparent and accountable quality control7 loop.

When I'm evaluating a factory, I don't just look at the machines; I look at their data systems8. A top-tier factory has sensors on every mold that track temperature and pressure in real time, for every single tire. Alarms should automatically trigger if any parameter deviates. This data should then be archived and linked to the tire's serial number. At Gescomaxy, we require this from our partners. It means if a tire ever has an issue, we can pull up its "birth certificate" and see its exact curing history. A supplier unwilling or unable to provide this level of data is a supplier with something to hide.

Your Curing Stability Checklist

Ask your supplier these questions to audit their process control:

| Question | What a Good Answer Looks Like | Why It Matters |

|---|---|---|

| "Do you have automated monitoring?" | "Yes, every press has real-time temp/pressure sensors that automatically halt production on deviation." | This removes human error and ensures consistency 24/7. |

| "Can you trace a tire to its curing data5?" | "Yes, each tire's serial number is linked to a full curing cycle report." | This proves accountability and allows for precise root cause analysis. |

| "How often do you calibrate your molds?" | "We have a strict schedule for sensor calibration and mold cleaning to ensure uniform heat transfer9." | This prevents issues like uneven heating10 and data drift. |

If a supplier can't confidently answer and provide proof for these, their curing process is not stable.

Conclusion

Curing stability1 is the hidden factor that dictates an OTR tire's true lifespan. Partnering with a supplier who proves their process control with data is the only way to ensure reliability.

Understanding curing stability is crucial for ensuring tire durability and performance, making it a key factor in tire selection. ↩

Procurement managers must navigate quality and performance issues, making informed choices essential. ↩

Vulcanization is a critical process that enhances rubber's properties, ensuring tires are durable and reliable. ↩

Traceability ensures accountability in production, allowing for better quality control and customer trust. ↩

Curing data ensures accountability and quality control, helping to guarantee tire performance and longevity. ↩

Pressure logs help monitor the curing process, preventing defects and ensuring tire reliability. ↩

Quality control is crucial for ensuring tire safety and performance, making it a key focus for manufacturers. ↩

Data systems enhance monitoring and quality assurance, leading to better tire performance and reliability. ↩

Heat transfer is vital in tire curing; understanding it can help prevent performance issues and extend tire life. ↩

Uneven heating during curing can cause rapid wear and failure; understanding this can improve tire selection. ↩