Your loader tires look fine, but then you spot them—cracks forming right at the shoulder. You replace them, but the next set does the same thing, forcing expensive downtime and replacements.

Shoulder cracking on loader tires1 is rarely a manufacturing defect. It's typically a structural mismatch2, caused by using a tire with a casing that can't handle the intense twisting and side forces unique to loader operations3.

I'll never forget a call from a scrapyard owner. He was furious. "Your tires are junk!" he said. "The shoulders are splitting on all of them after just a few hundred hours." I drove out to his site and saw his loaders performing tight, aggressive turns on a mix of concrete and metal debris. He was using a standard radial tire4, famous for its smooth ride and long wear in trucking. The problem wasn't the tire's quality; it was its design. He was using the equivalent of a long-distance running shoe for a rock-climbing competition. The tire's flexible sidewalls, great for heat dissipation on long hauls, were being torn apart by the twisting force. This experience taught me that for loaders, the shoulder is where the battle is won or lost.

Are You Using a Radial Tire Where a Bias Tire Should Be?

You bought radial tire4s for their well-known benefits like a larger footprint and better heat management. But now they are failing prematurely at the shoulder on your high-torque, constant-turning loader.

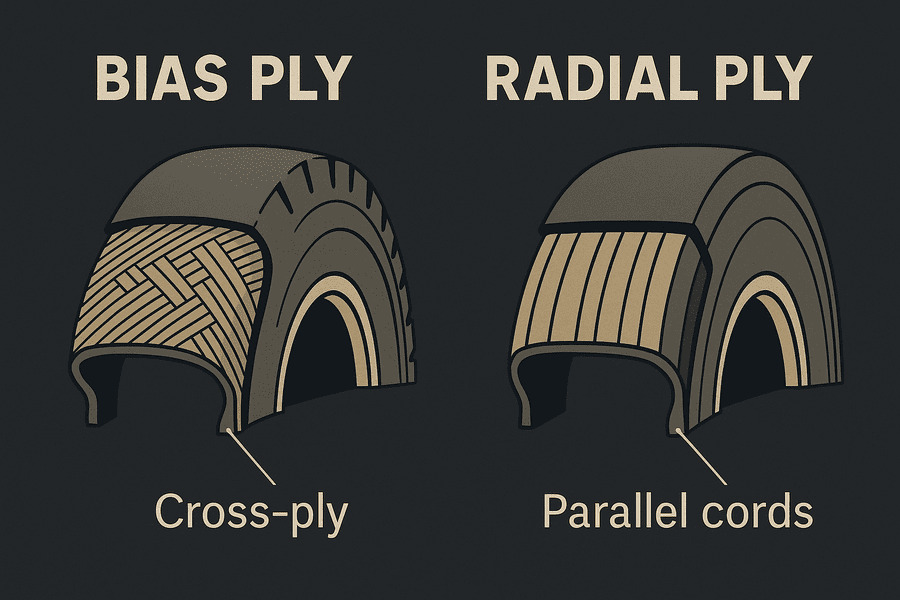

For loaders in harsh, twisting environments like quarries or scrapyards, a bias tire5 is often superior. Its rigid, cross-ply construction and thicker sidewalls provide the torsional strength6 needed to resist shoulder tearing, outperforming a more flexible radial tire4.

The choice between bias and radial isn't about which is "better" overall; it's about which is right for the specific machine and job. Loaders don't operate like haul trucks. They are constantly twisting, lifting, and pushing, which puts enormous lateral force on the tire's shoulder. A bias tire5 has a "stronger backbone." Its plies crisscross, creating a stiff and unified casing that resists these twisting forces. A radial tire4's sidewalls are designed to flex independently from the tread, which is fantastic for long, straight runs at speed because it reduces heat. But in a scrapyard, that flex becomes a weakness. The constant side-slip and pivoting action can overwhelm the flexible sidewall, leading directly to the shoulder cracking you're seeing. It’s a classic case of the wrong tool for the job.

Bias vs. Radial for Loader Applications

| Feature | Bias Tire | Radial Tire |

|---|---|---|

| Construction | Cross-ply, stiff casing | Flexible sidewalls |

| Best For | Low speed, high torque, twisting | Long cycles, higher speed, heat |

| Ideal Environment | Quarries, scrapyards, waste sites | Ports, large yards, logistics |

| Key Advantage | Superior resistance to side-impact and twisting forces. | Lower rolling resistance, better heat dissipation. |

| Weakness | Can overheat on long, fast runs. | Shoulder can be vulnerable to twisting forces. |

Why Is the Tire's Internal 'Skeleton' More Important Than Its Tread?

You focus on deep tread and aggressive patterns when buying tires, assuming more rubber means more life. Yet, your tires are still being taken out of service by punctures or separations, with plenty of tread left.

A tire's real durability comes from its internal casing7—the 'skeleton' of plies, belts, and reinforcements. This structure determines puncture resistance8 and fatigue life. The tread is just for traction and wear; the casing is what ensures survival.

Customers often tell me, "I want the tire with the deepest tread." I understand the logic, but it's like judging a building by the thickness of its paint. The real strength is in the foundation and frame. For a loader tire, this internal skeleton is everything. The number of body plies and their angle determine the tire's ability to handle the machine's immense torque without tearing itself apart. The strength of the steel belt package under the tread is what stops a sharp rock from becoming a catastrophic puncture. The thickness of the rubber and reinforcement in the shoulder and sidewall is what resists the constant "twist-and-lift" action of a loader. When a tire fails at the shoulder, it's the skeleton that has broken. A tire with a weaker casing but deeper tread is a bad investment. It will fail long before you ever use all that rubber.

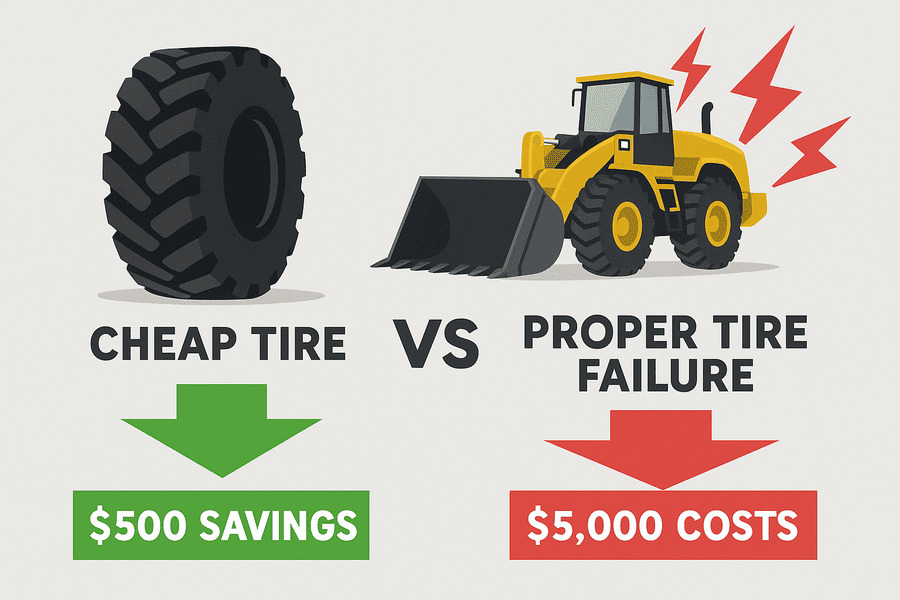

How Can a 'Cheaper' Tire End Up Costing You 10x More?

You choose a lower-priced tire to save 20% on your initial purchase. But when one tire fails unexpectedly, it shuts down a key machine for a day, erasing your initial savings and then some.

The cost of a single tire failure9 caused by the wrong structure—including machine downtime, lost production, and labor—is often 5 to 10 times greater than the initial price difference between a cheap tire and a properly specified one.

This is the most critical calculation a purchasing manager can make. Let's say you save $800 by choosing a tire with a weaker casing. It looks like a smart move. But that tire's structure isn't matched to your loader's workload, and it fails at the shoulder after 1,000 hours. Your loader, a critical piece of your operation, is now down for 5 hours while you source and fit a replacement. If that loader's downtime costs10 your operation $2,000 per hour, you've just incurred a $10,000 loss in productivity. Your initial $800 savings has turned into a massive expense. This is why I always say that the casing choice is the real cost decision. A more expensive tire with the correct internal structure for your job isn't a cost; it's insurance against the far greater expense of failure.

Conclusion

Shoulder cracking is a clear sign of a structural mismatch2. To solve it, prioritize the tire's internal casing7 over its tread pattern11 or price, and choose a structure built for twisting forces.

Understanding the causes of shoulder cracking can help you choose the right tires and avoid costly downtime. ↩

Learn about structural mismatch to ensure your tires are suited for the specific demands of loader operations. ↩

Learn about the unique challenges of loader operations to better understand tire requirements. ↩

Discover why radial tires may not be suitable for loaders and how they can lead to premature failure. ↩

Explore the benefits of bias tires, which can outperform radial tires in harsh, twisting environments. ↩

Understanding torsional strength can help you select tires that withstand the demands of loader operations. ↩

Understanding the role of internal casing can help you make informed tire choices for durability and performance. ↩

Learn how puncture resistance contributes to tire longevity and prevents costly failures. ↩

Identifying common causes of tire failure can help you prevent downtime and improve operational efficiency. ↩

Understanding downtime costs can guide you in selecting tires that minimize operational disruptions. ↩

Explore how tread patterns influence tire performance and why they shouldn't be the sole focus when choosing tires. ↩