Struggling with tire performance1 and high costs? The wrong construction wears out fast, risking downtime. Understanding the steel belt plus nylon cap structure gives you the performance you need.

The key advantage is combining strength with stability. A steel belt provides a rigid, stable footprint2 for even wear and excellent traction. The nylon cap adds durability and prevents belt separation3 at high speeds, outperforming full nylon in demanding, heavy-load applications.

That's the short answer. But the real value comes from knowing exactly how these materials work together. I've spent years explaining this to clients, and the details are what make the difference between a good choice and a great one. Let's break down the fundamentals.

What’s the core structural difference between a Steel Belt and a Full Nylon tire?

Are you confused by technical tire terms? Choosing based on jargon can mean getting a tire that fails you. Let's look at the simple, core differences between the two main structures.

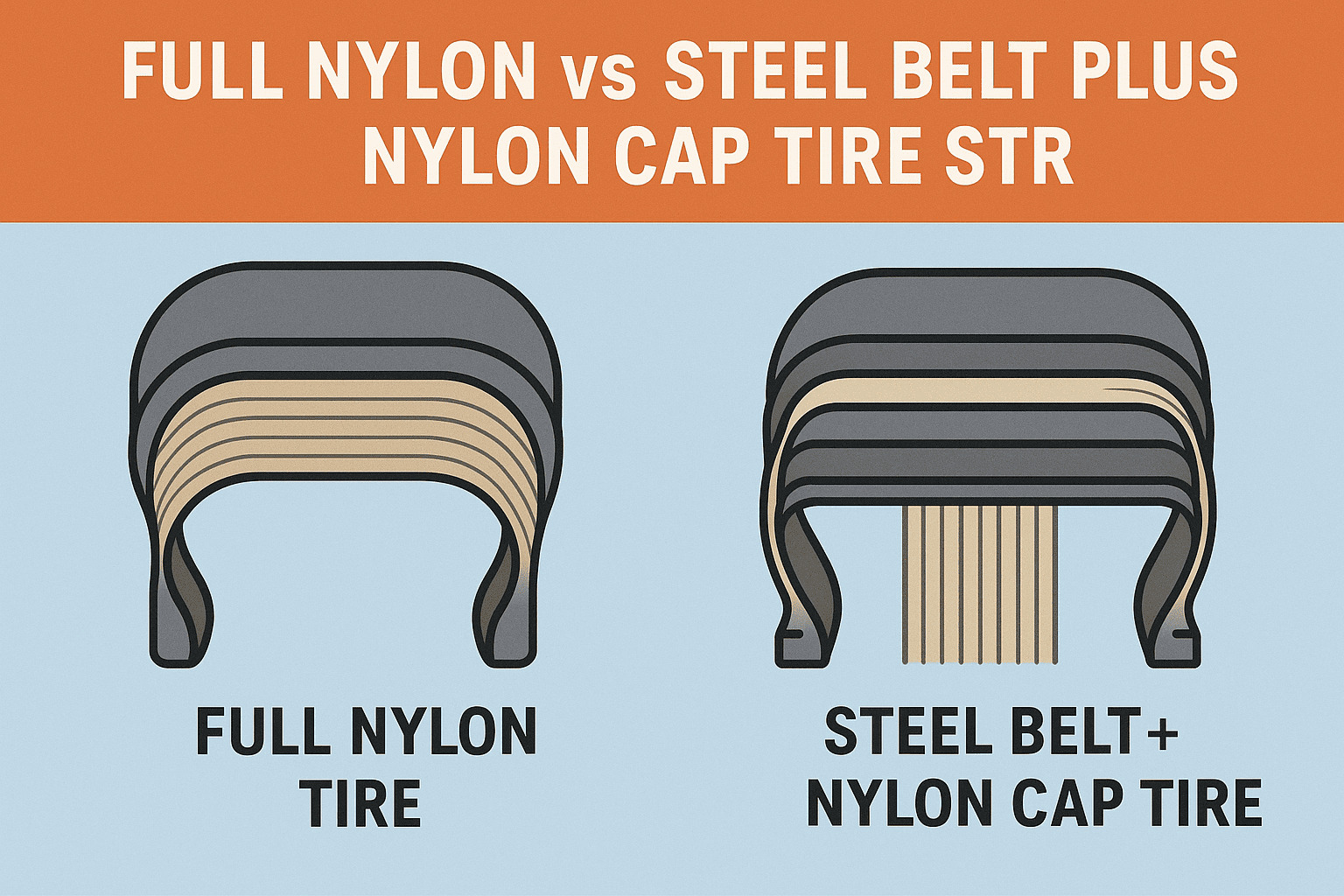

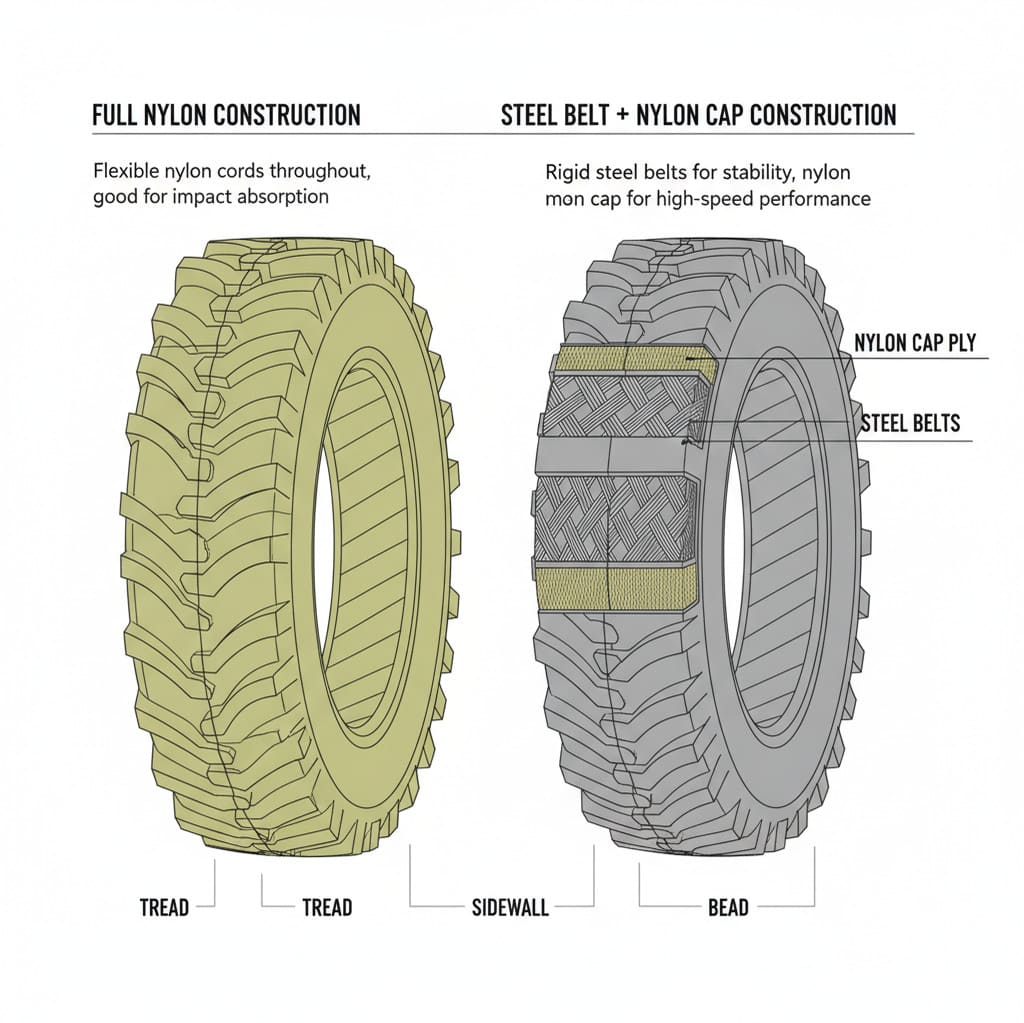

A full nylon tire uses layers of nylon fabric for its entire carcass, making it flexible and impact-resistant. A steel belt tire uses a steel foundation for rigidity and footprint stability. The "hybrid" adds a nylon cap over the steel for extra protection.

Let's dive deeper into what these materials do. I often explain to my clients that you're choosing between flexibility and rigidity. Each has its place.

The Foundation: Carcass Material

The core of the tire, its carcass, dictates its basic behavior. A full nylon tire is built with multiple layers, or plies, of nylon cords. Nylon is known for being tough yet flexible. This allows the tire to absorb shocks from rough terrain, which is why it's popular in agriculture.

A steel-belted tire has a foundational structure made of steel cords. Steel is much more rigid than nylon. This rigidity creates a very stable base. It prevents the tread from squirming or deforming under heavy loads or high torque. This is the primary difference.

The Reinforcement: Belts and Caps

Here is how they compare structurally:

| Feature | Full Nylon Tire | Steel Belt + Nylon Cap Tire |

|---|---|---|

| Main Carcass | Multiple plies of nylon fabric | Radial plies, often polyester or nylon |

| Belt Package | More nylon plies | Two or more belts of steel cords |

| Extra Layer | None | A "cap" ply of nylon over the steel belts |

| Key Trait | Flexibility, Impact Absorption | Rigidity, Footprint Stability |

The steel belt and nylon cap combination is a sophisticated design. The steel provides the strength, and the nylon cap acts like a harness, holding the steel belts tightly in place. This prevents the belts from expanding or separating due to heat and centrifugal force, especially at higher speeds.

In which specific applications does a steel belt with a nylon cap truly excel?

Ever bought a premium tire that failed early? The application might have been wrong for its design. Knowing where a steel belt with a nylon cap shines prevents costly mistakes.

This structure excels in high-load, high-speed applications where heat and stability are critical. Think of heavy-duty trucks4 on highways, large loaders in quarries, or industrial vehicles5 that run constantly. It provides the best defense against heat buildup6 and tread separation.

I once had a client running a fleet of port vehicles. They were burning through full nylon tires because of the constant, heavy stop-and-go action on abrasive concrete. The tires were overheating and the tread was wearing unevenly. We switched them to a steel belt with a nylon cap design. Their tire life almost doubled. The steel belts kept the tread flat for even wear, and the nylon cap helped manage the heat.

High Load and Torque Scenarios

Heavy machinery places immense stress on tires. A rigid footprint is essential for safety and efficiency.

- Loaders and Earthmovers: These machines carry tons of material. The steel belts prevent the tire from bulging under the weight, ensuring the full tread face stays on the ground for maximum traction and stability.

- Heavy-Duty Trucks: On the highway, truck tires face constant flexing and heat buildup6. The steel belts provide stability, while the nylon cap is crucial for preventing belt separation3, a common failure mode at high speeds.

Environments with High Abrasion

Surfaces like concrete and asphalt can wear down a tire quickly if the tread isn't stable.

| Application | Primary Challenge | Why Steel Belt + Nylon Cap Wins |

|---|---|---|

| Long-Haul Trucking | High Speed, Heat Buildup | Nylon cap prevents belt separation3. Steel provides stability for fuel efficiency. |

| Quarry/Mining | Heavy Loads, Sharp Rocks | Steel belts offer puncture resistance7. The rigid tread wear8s more evenly. |

| Port Terminals | Constant Use, High Abrasion | A stable footprint from steel belts reduces wear from scrubbing and turning. |

| Industrial Vehicles | Continuous Operation | Excellent heat dissipation and durability extend tire life in 24/7 settings. |

In these cases, a full nylon tire's flexibility becomes a weakness. It would deform more under the load, leading to a less stable footprint, uneven wear, and more heat generation.

When is a full nylon tire the smarter and more cost-effective choice?

Are you automatically choosing the "stronger" steel-belted option? Sometimes, the more flexible and affordable full nylon tire is actually the better tool for the job, saving you money.

A full nylon tire is the smarter choice for low-speed, rough-terrain applications where impact resistance9 is more important than stability. It excels in agriculture, forestry, and on smaller construction equipment where sidewall damage from rocks and stumps is a major concern.

Over the years, I've seen many customers in the agricultural sector stick with full nylon (bias) tires, and for good reason. Their main enemy isn't heat or speed; it's unexpected impacts. A farmer driving over a hidden rock or stump needs a tire that can flex and absorb that hit without puncturing. The multiple, crisscrossing nylon plies in a bias tire provide excellent sidewall strength and a "cushioning" effect.

Where Flexibility Beats Rigidity

The forgiving nature of nylon is its greatest asset in certain environments.

- Agriculture: Tractor tires need to operate on soft soil and uneven ground. The flexibility of a nylon tire allows it to create a wider footprint at low pressure, reducing soil compaction. Its durable sidewalls resist damage from field debris.

- Forestry: Skidders and forwarders navigate extremely rough and unpredictable terrain. A nylon tire's ability to deflect around obstacles is critical to avoiding punctures and keeping the machine moving.

Cost-Effectiveness Analysis

For these applications, a steel-belted tire can be overkill and sometimes even a disadvantage.

| Application | Primary Challenge | Why Full Nylon Wins |

|---|---|---|

| Farming (Tractors) | Uneven Ground, Sidewall Impacts | Flexibility absorbs shocks. It's more forgiving on the sidewall and often cheaper. |

| Small Construction | Rough Sites, Debris | Excellent puncture and cut resistance from its multi-ply construction. |

| Low-Speed Off-Road | Punctures, Obstacles | The entire tire body is built for toughness, not just the tread area. |

In these scenarios, the rigidity of a steel belt doesn't provide a significant advantage. The speeds are too low for heat to be a major issue, and the terrain demands a tire that can conform and endure impacts. A full nylon tire provides the necessary durability at a lower price point, making it the more intelligent economic choice.

Conclusion

Choosing the right tire construction is simple. Use steel belt with a nylon cap for high-speed, heavy-load jobs. Pick full nylon for low-speed, rough-terrain work requiring impact resistance9.

Learn strategies to enhance tire performance, ensuring safety and efficiency in high-load scenarios. ↩

Understand the significance of a stable footprint for tire longevity and performance under heavy loads. ↩

Find out how to prevent belt separation, a common issue that can lead to tire failure. ↩

Discover the best tire options for heavy-duty trucks to ensure performance and safety. ↩

Learn about the essential tire features that enhance performance in industrial settings. ↩

Learn about the impact of heat buildup on tire performance and how to mitigate it. ↩

Discover key features that improve tire puncture resistance, crucial for rough terrains. ↩

Learn about the factors that affect tire tread wear and how to extend tire life. ↩

Explore the importance of impact resistance in tire selection for various applications. ↩