For years, you've competed on tread depth, compound durability, and load capacity. But now, your biggest clients are asking questions you can't answer—about carbon footprints1 and material sources, not just performance.

The competitive edge in agricultural tires is shifting from physical properties to sustainability data. Major equipment manufacturers and new regulations now require suppliers to provide verifiable data on a tire's entire lifecycle, including its carbon footprint, material traceability2, and ESG compliance3.

This isn't a far-off trend; it's happening right now. I was in a meeting with a major European OEM last year, and the conversation was a real eye-opener. We spent the first ten minutes on the tire's technical specs and the next hour on our material traceability2 reports and our factory's carbon emissions data. The procurement manager was clear: if we couldn't provide this information, we wouldn't even be considered for their next platform, no matter how good the tire was. The rules of the game have fundamentally changed.

Why are bio-materials and carbon footprints1 suddenly more important than tread compounds?

You've perfected your rubber compounds for maximum wear and traction. You believe a superior product will always win. But you're finding that RFPs now have entire sections on environmental impact4 that are worth more points than performance metrics.

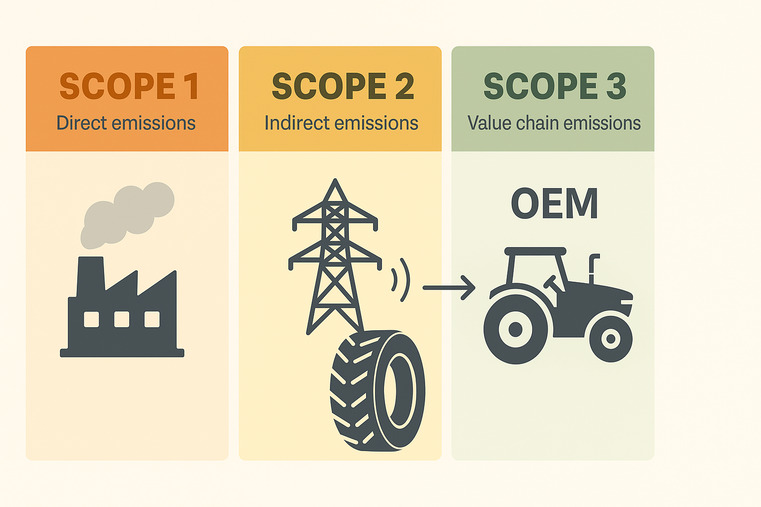

Original Equipment Manufacturers (OEMs) are now responsible for the total carbon footprint of their machines, which includes every component. Your tire's environmental impact4 is now part of their official corporate sustainability report, making your green credentials5 a non-negotiable purchasing requirement.

For a long time, "green" was just a marketing buzzword. Now, it's a line item in an audited financial report6. Regulations like the EU's Corporate Sustainability Reporting Directive (CSRD) force large companies to disclose their "Scope 3" emissions—which means the emissions from their entire supply chain. A tractor manufacturer can have the greenest factory in the world, but if they buy tires with a massive carbon footprint, their overall numbers will look terrible. This is why bio-based rubber7, renewable fillers8, and low-carbon carbon black are no longer optional. They are the price of entry to the modern supply chain.

The New Spec Sheet

The criteria for what makes a "good" tire has expanded. The old metrics still matter, but a new set of sustainability metrics has become equally, if not more, important.

| Old Competitive Factors | New Competitive Factors |

|---|---|

| Tread Life & Durability | Product Carbon Footprint (PCF)9 |

| Traction & Flotation | Percentage of Bio-Based/Recycled Materials |

| Load Index & Speed Rating | Raw Material Traceability (e.g., sustainable natural rubber10) |

| Unit Price | Life Cycle Assessment (LCA)11 Data |

| Manufacturing Quality (ISO 9001) | Compliance with Environmental Regulations (e.g., REACH) |

As a supplier, if your spec sheet only lists the left column, you are already falling behind. The winners of tomorrow will compete and win based on the right column.

How can a simple tire become a major ESG risk for a multi-billion dollar company?

You see your product as a component, one of thousands on a complex machine. It's easy to think its impact is small. But from the OEM's perspective, every single component is a potential point of failure—not just mechanically, but for their brand reputation and regulatory standing.

A tire with an untraceable supply chain or a high carbon footprint creates significant ESG (Environmental, Social, and Governance) risk. It can damage an OEM's brand, lower their sustainability rating, and even lead to fines or restricted market access under new environmental laws.

Imagine this scenario: a major tractor brand launches a new "eco-friendly" electric model. Then, an investigative report reveals that the rubber in their tires was sourced from a region linked to deforestation. The reputational damage would be immense. The "eco-friendly" claim would be destroyed. This is the kind of risk that keeps supply chain managers up at night. They are not just buying a tire from you; they are inheriting your entire supply chain's ethical and environmental baggage. If you cannot prove your materials are clean, you are not a supplier; you are a liability. This is why we at Gescomaxy emphasize our strict quality control and material testing—it's about de-risking our clients' businesses.

Your Tire, Their Report Card

In the world of ESG, a company is graded on its weakest link. Your tire is a direct input into your client's performance in several key areas:

- Environmental: Your product's carbon footprint, water usage, and waste generation directly impact their environmental disclosures.

- Social: Your labor practices and the sourcing ethics of your raw material suppliers (e.g., conflict minerals, fair labor) fall under their social responsibility umbrella.

- Governance: Your ability to provide transparent, audited data and comply with international standards is a reflection of good governance that they must be able to rely on.

In this context, a supplier who provides comprehensive, transparent sustainability data is not just selling a tire; they are selling peace of mind.

What data will you actually need to provide to win future contracts?

You know you need to be more "sustainable," but the term feels vague. You need to know what specific, tangible proof your customers will demand so you can prepare your business for the future.

To win future contracts, you must be prepared to provide a "sustainability data package12." This includes a formal Life Cycle Assessment (LCA)11, a verified Product Carbon Footprint (PCF)9, certificates of material origin, and proof of compliance with key international environmental and social standards.

The time for vague green claims is over. The market now demands proof. As a supplier for over a decade, I've watched this evolve from a "nice-to-have" to a "must-have." We are building these capabilities because we know that in a few years, you won't even get a request for a quote without them. Your customers are being audited, and they will, in turn, audit you. Being prepared with the right data is the only way to secure your place in the supply chains of the future.

Your Future Data Checklist

Start preparing now to answer these questions with certified proof:

- What is the Product Carbon Footprint (PCF)9? You will need a verified number, measured in kg CO2e per unit, that covers everything from raw material extraction to your factory gate ("cradle-to-gate").

- Can You Provide a Life Cycle Assessment (LCA)11? This is a more comprehensive report detailing the environmental impact4s across multiple categories, including water use, ecotoxicity, and ozone depletion.

- Where Do Your Materials Come From? You will need traceability documents to prove your natural rubber is sustainably sourced and that other key materials do not come from regions with ethical or environmental red flags.

- Are You Compliant? You'll need certifications like ISO 1400113 (Environmental Management) and documentation proving compliance with regulations like REACH in Europe.

This isn't just paperwork. This data is becoming as important as the tire's physical dimensions and performance ratings.

Conclusion

The new competitive battlefield for agricultural tires is not in the field, but in the data. Your ability to prove a lower carbon footprint and a cleaner supply chain will soon matter more than tread depth.

Understanding carbon footprints is crucial for suppliers to meet new sustainability demands. ↩

Material traceability is essential for ensuring sustainable sourcing and compliance. ↩

ESG compliance is becoming a key factor in supplier selection and corporate responsibility. ↩

Understanding environmental impact is essential for suppliers to align with client sustainability goals. ↩

Improving green credentials is essential for suppliers to remain competitive in the market. ↩

Audited reports are increasingly required to demonstrate transparency in sustainability practices. ↩

Bio-based rubber is key to reducing carbon footprints and meeting sustainability goals. ↩

Renewable fillers can significantly lower the environmental impact of tire manufacturing. ↩

Understanding PCF is essential for suppliers to demonstrate their environmental impact. ↩

Sustainable natural rubber is critical for reducing the ecological footprint of tire production. ↩

LCA provides a detailed view of a product's environmental impact throughout its lifecycle. ↩

A comprehensive sustainability data package is vital for winning contracts in today's market. ↩

ISO 14001 certification is crucial for demonstrating commitment to environmental sustainability. ↩